Introduction

Thermoforming packaging machines are used for packaging food and pharmaceutical.

One of the most important features of this machine is accurate packaging using the MAP method, aimed at increasing the shelf life of the product.

The technical standards used in this machine ensure that during its use (product packaging), the following benefits are accompanied for the manufacturer.

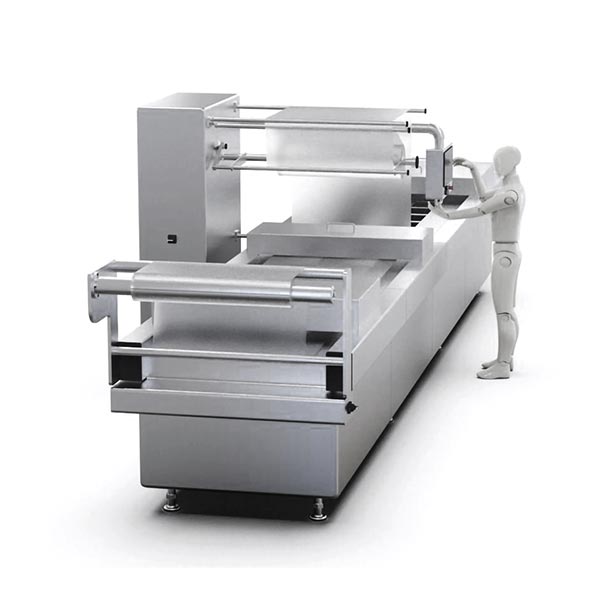

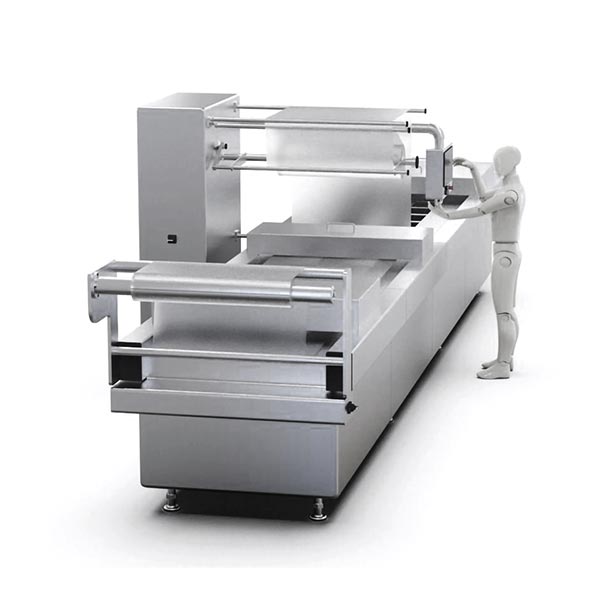

Thermoforming packaging machines manufactured by West Asia Steel Machinery Company are used for packaging food and pharmaceuticals in plastic containers.

The thermoforming packaging machine is one of the machines designed and manufactured by West Asia Steel Company. This machine is suitable for producers aiming to have packaging with a different shape compared to other packaging methods. The most significant difference between a thermoforming machine and a tray sealer is that in the thermoforming method, the tray is formed by the machine itself, whereas in a tray sealer, the tray must be purchased ready-made from outside.

Advantages of the thermoforming packaging machine by West Asia Steel

- High-quality and strong sealing

- Accurate and unique cutting systems

- The control panel of the machine is easily movable and accessible.

- Operator safety is ensured during the use of the machine.

- Mold changing and settings are simple.

- The structure, frame, and connections are made of durable stainless steel.

Operation of the thermoforming machine

- The thermoforming machine can package products inside plastic trays. The difference between this machine and tray sealers (seal vacuum machines) is that thermoforming machines manufacture the tray too. The film is placed in the machine and then formed by a forming mold, additionally, the packaging takes shape in the next stage and finally is cut in the final mold.

- This machine can be equipped with a UV tunnel and various types of fillers, after the products are filled into the trays, they are guided to the sealing mold, if it is necessary, vacuuming and gas injection take place. Subsequently, the film is sealed onto the tray, then cut in the next stage, and finally is moved out of the machine.

- At the end of the machine, an automatic rower, jet printer, traffic table, and even an automatic lidder can be installed to complete the packaging line.

Film of the machine

Dietary diversity is expanding, and consequently, types of packaging are also increasing. Therefore, it can be said that each packaging method has its place on supermarket shelves. West Asia Steel Machinery Company provides various packaging solutions in trays and plastic pouches.

The following films can be used in packaging by thermoforming machines.

- Soft and flexible film

- Hard film (such as disposable trays)

Packaging methods

Simple packaging method

In this method, the focus is on packing the product in a simple way and protecting it against environmental pollution and possible damages.

Packaging with vacuum method

In this method, the product is completely vacuumed and biochemical degradation is reduced.

Packing with modified atmosphere method (MAP)

The atmosphere in the tray is replaced by a specific gaseous compound to extend the shelf life of the product.

For example, the gaseous composition of carbon dioxide, nitrogen and in some cases, oxygen can be used, causing the color and shape of the product to be preserved for a longer period of time.

Packaging by Skin Method

Your product is packed by a film that is placed in the form of a shell on it. This coating, while having transparency and attractiveness, can minimize the atmosphere inside the package and keep the freshness of the product for a longer time.

Packaging with skin method has different types:

Low – Medium – High

Cutting system of the machine

Cutting system in thermoforming packaging machine of West Asia Steel machinery Company can be done by the following method

Transverse and longitudinal cutting by blade

This method is used for quadrangle trays. In this case, the corners of the tray will be sharp, and the machine settings will be easier to manufacture a tray with other dimensions.

Top of Form

Transverse cutting by Punch and Die block – longitudinal cutting by blade

In this method, transverse cutting of containers can be done by Punch and Die block with a special form, then their longitudinal cutting is done by circular blades that are rotating.

Complete cut by Punch and Die block

This method can be used for trays with special shapes. The tray can has any shape, as there is no limit to cutting.

All cuttings can also include:

- Zigzag Cutter

- Pendant hole

- a point for easier removal of the film from the tray

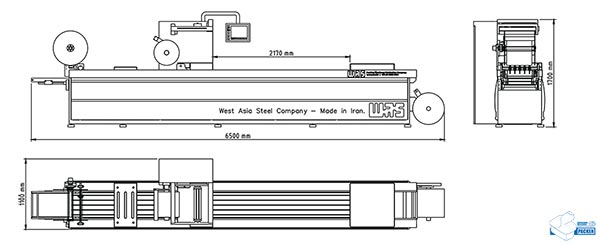

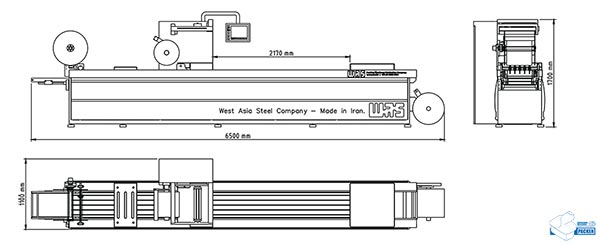

Schematic and dimensions of the machine

Technical Specifications

- Drive: Servo Motor

- Vacuum pump: 100 cubic meters and larger dimensions are provided outside the machine.

- The system of temperature controlling: usage of PID system for controlling temperature of the machine

- Electrical Power: 8 kw

- Electrical current: 14 A

- Machine speed: up to 12 cycles per minute – depending on the product and the type of packaging

- Maximum machine dimensions: L6.5 * w1.5 * h2 m

- Tray dimensions: 418*349 with a maximum depth of 90 mm

- Package Material: PA-PE/PET-PE/PVC-PE/PS

- Film material on packages: aluminum foil, plastic film, metallized

- Easy open and hard open

- Package shape: Designed free of charge according to customer’s request

- Tray Production Method: By positive air pressure and negative vacuum pump pressure

- Cutting system: smooth – zig-zag – round corner – complete cutting with special form

- Capability to work with Printed and unprinted film

- Mold material: Aluminum alloy grade 1 – Fully coated

- Material of Seal mold: Aluminum Alloy by Teflon coating and high thermal conductivity capacity

- Cutting mold material: Steel with good cutting capability and long lifespan

- Electrical Panel Material: Stainless Steel 304L

- Machine control system: PLC with HMI colored control panel with good quality brand, using 2 languages of Persian and English, user-friendly

- System Operation: Pneumatic – Electronic – Mechanical

- Required air pressure: 6 to 8 bar

- Usage of cold water: 90 liters per hour (with circulation system)

- Modified Atmosphere System (MAP) is available on the machine (the additional option)

- Film Width: 422 mm

- High quality electronic and pneumatic components

- Outlet conveyor

- Washable

Auxiliary equipment:

- Capability to install various fillers on the machine, such as fillers for diluted and concentrated liquids and weighing fillers.

- Capability to install labelers and jet printers on the machine.

- For requesting other options, it is necessary to have a session with our technical and engineering department.

Applications of machine in packaging

A variety of cold prepared food (Such as Olivier salad, pasta( and semi-prepared food

- pickles (pickled cucumbers and olives)

- meat products(Red meat, ground meat and chicken)

- Processed meat products(Sausage, nuggets, hamburgers)

- Sea foods (such as shrimp, fish)

- Vegetables, fruits and salad

- Packaging of dairy products

- Bread and confectionery

- Different types of medical devices and products

Different types of cosmetics