Medical devices enables treatments and surgeries such as treating a sprained ankle or implanting an artificial knee. According to the World Health Organization's definition, a medical device can be any instrument, apparatus, implement, machine, appliance, implant, reagent for in vitro use, software, material, or other similar or related article intended by the manufacturer to be used, alone or in combination, for medical purposes. Medical devices can be sterile or non-sterile.

Purpose of Medical Equipment Packaging

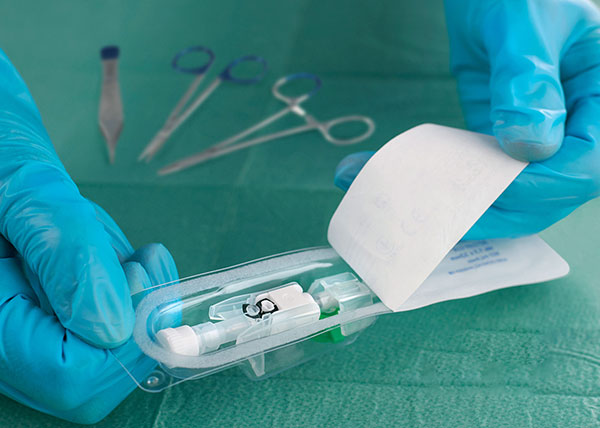

Without proper packaging, surgeons and healthcare specialists would not be able to use medical devices. The packaging of a medical device consists of a combination of sterile layers and protective packaging (for sterile equipment). Protective packaging is used to prevent damage to the sterile covering and its contents from the time of manufacture until the time of use. Protective packaging can also be used for non-sterile implants and tools. Packaging minimizes the risk of microorganism contamination and ensures that the sterilized contents can be safely used, thereby minimizing safety risks for the end user and patient under the considered usage conditions.

Importance and Benefits of Medical devices Packaging

The packaging of medical equipment is highly important due to the high sensitivity of these items, and even a small error in packaging can sometimes cause harm to the patient. Therefore, appropriate and correct packaging of medical equipment is of utmost importance. Some of the benefits of medical equipment packaging include:

Importance and Benefits of Medical Equipment Packaging

The packaging of medical equipment is crucial due to its high sensitivity, and even a minor error in packaging can potentially harm the patient. Therefore, appropriate and correct packaging is of utmost importance. Some benefits of medical equipment packaging include:

- Protection from Environmental Damage: Proper packaging protects medical equipment from environmental damage such as impact, moisture, dust, sunlight, and other factors. This benefit can reduce the costs associated with returning damaged medical devices.

- Reducing Health Risks: Proper packaging helps reduce health risks for patients, medical personnel, and the community. Medical devices can sometimes be exposed to contamination and dangerous bacteria. Suitable packaging helps mitigate these risks.

- Increasing the Shelf Life of Medical Devices: Proper packaging maintains medical devices in favorable conditions, preventing a reduction in its shelf life and quality due to adverse conditions.

- Enhancing Efficiency and Productivity: Maintaining medical device in proper packaging can maximize efficiency and productivity in medical settings.

- Compliance with Safety Standards: Using appropriate packaging ensures that medical equipment meets safety standards and health regulations. Adhering to these guidelines ensures the safety of patients, medical personnel, and the community against health and safety risks.

- Facilitation of Transportation: Proper packaging ensures that medical equipment can be transported safely and reach its final destination without issues.

- Enhancing Credibility and Trust: Appropriate packaging enhances the credibility and trust of patients and medical personnel in the medical equipment. It demonstrates that the equipment has been given special attention and packaged according to higher standards.

Methods of Sterilization of Medical Devices

The method of sterilization affects the choice of materials used for packaging sterile products. The various methods of sterilization include gamma radiation, ethylene oxide (EtO), electron beam (E-Beam), and autoclaving. For products that require gamma sterilization, the packaging material must be breathable to allow for sterilization while also protecting the product from microorganisms. Common packaging components that can be used for gamma sterilization include Tyvek paper, nylon bags, and PETG containers with Tyvek paper. Ethylene oxide is a gas that can leave residues which can be very harmful if not properly vented/aerated. When designing for EtO sterilization, the placement of labels and instructions for use is very important. Packaging materials used for gamma sterilization can also be used for EtO.

Standards for the Packaging of Medical Devices

ISO 11607 standard: This standard details the specifications, characteristics, and materials required for sterile packaging of medical devices, considering a wide range of product features and sterilization methods.

ISO 11607-2 standard: This part of the standard outlines the requirements for validation and verification of sealing and packaging processes for sterile medical devices and sterile medical products.

The types of tests that need to be conducted to ensure proper packaging include:

- Visual Inspection

- Peel Test

- Seal Strength Test

- Penetration Test

- Dye Penetration Test

- Air Leak Test

Types of Packaging Containers

There are various types of packaging materials that can be used for both sterile and non-sterile medical devices. Medical equipment typically has primary, secondary, and sometimes tertiary packaging. Primary packaging can be a non-sterile cover, a single-layer sterile cover, a double-layer sterile cover, or a carton. Tertiary packaging is usually for shipping and is used for delivery to the customer.

For sterile equipment, many types of coverings can be used. The packaging materials include nylon/nylon, Tyvek paper/Mylar film, foil/nylon, foil/Mylar, and foil/foil. Tyvek is made from continuous, randomly oriented, high-density polyethylene (HDPE) fibers, which provide strong resistance against microbes and other contaminants. Foil offers excellent protection against ultraviolet (UV) light, moisture, and oxygen. The mentioned packages can have single-layer or double-layer sterile covers. Bag packages are generally used for smaller and lighter equipment (such as screws and small consumables), while containers are typically used for heavier and bulkier equipment (such as knee and hip implants). Most rigid containers are made of polyethylene terephthalate glycol (PETG), and their lids can be made of Tyvek, foil, or in some cases, medical-grade paper.

Foldable cartons are used to hold both sterile and non-sterile packaged components. Most modern cartons are made from solid bleached sulfate (SBS) and typically use 20, 22, or 24-point (pt) caliper cardboard. Foldable cartons with corrugated liners and flutes are also used to provide additional structure and strength. Cartons can be either flat or thick. The packaging engineer usually determines the style of carton needed based on what will be placed inside the carton.

Attractively shaped containers can enhance the packaging's appeal and positively impact sales. With its expertise in the packaging machinery industry, West Asia Steel Company can offer customers customized molds for manufacturing containers.

Therefore, customers who need uniquely shaped containers for packaging their medical products, distinct from the general containers available in the market, can present their design. At West Asia Steel, we create an initial prototype using a 3D printer and after your approval as the customer, we manufacture the mold and manufacture the desired container in your preferred quantity.

Since we at West Asia Steel specialize in packaging a wide range of food products as well as medical and pharmaceutical items, we can provide you with the necessary information on selecting the right type of film and suitable packaging container for your product.

You can consult with West Asia Steel regarding the selection of the best container for packaging medical products and equipment, and obtain your suitable container at the best price.

Protective Covering

Some medical devices require a protective covering that acts as a barrier against oxygen or moisture. Understanding the product and the type of protection needed is very important. If the packaging materials are chosen incorrectly, the product may become corroded or contaminated.

Performance of Packaging Materials

Understanding how packaging behaves under specific climatic conditions over a certain period is very important. This can be assessed by conducting an Accelerated Aging (AA) test along with Real-Time (RT) aging tests. Over time, the seal can become soft and loose. This can cause the materials to delaminate or even change color. Today, packaging materials must be able to maintain their stability for up to 10 years under the typical climatic conditions of healthcare facilities.

Packaging Process

Once a packaging system is selected and validated, having the correct sealing equipment for packaging in the production environment is important. Whether sealing nylon bags or containers, the sealing parameters must ensure that a good seal is achieved every time. The seal strength should not be so high that the customer or end-user cannot open the sterile package or container.

As a result, the appropriate packaging material should be selected based on product requirements such as sterilization method or sensitivity to moisture or oxygen. Ultimately, a packaging cover, sterile or non-sterile, should be used that can withstand transportation hazards and climatic conditions.

Types of Medical Equipment Packaging Machines

Here, we will examine the optimal methods for packaging medical equipment using various packaging machines:

Automatic Tray Sealer Packaging Machine

The steps for packaging medical devices using this machine are as follows:

- Loading the Pre-made Trays:

- The pre-made trays are placed onto the machine either automatically by an automatic denester or manually.

- Filling the Trays:

- The product is loaded into the trays either automatically by an automatic filling machine or manually.

- Sealing the Trays:

- The trays containing the product are guided into the machine's mold where they are vacuum-sealed and packaged. During this stage, a film is sealed onto the tray.

- Labeling the Trays:

- After sealing, the packaged trays can be directed under a labeling machine or jet printer by considering the opinion of customer where the date and other information are printed onto them.

The automatic tray sealer packaging machine is one of the products manufactured by West Asia Steel Company, featuring the following characteristics:

- Fully automatic with easy startup and settings adjustments by the operator

- Adjustable for different container sizes

- Various options available according to customer needs

For more information, you can view the page for the automatic tray sealer packaging machine.

The Semi-automatic Tray Sealer Packaging Machine

The semi-automatic tray sealer packaging machine is used for daily packaging on a small to medium scale. This machine is also utilized in stores and small businesses.

The operation of the machine is as follows: after placing the containers filled with the product onto the mold, the operator must rotate the machine table 180 degrees. Then, by pressing the buttons, the operator initiates the packaging process.

The features of the semi-automatic tray sealer packaging machine include:

- Suitable for low to medium packaging capacity

- Requires little space

- Affordable and easy to use

- Various options available according to customer needs

For more information, you can view the page for the semi-automatic tray sealer packaging machine.

Vacuum Chamber Packaging Machine

The vacuum chamber packaging machine (single chamber and double chamber) is used for packaging various products, including medical supplies, in plastic bags. The features of this machine include:

- Packaging products with complete vacuum or MAP (Modified Atmosphere Packaging) method

- Equipped with oil rotary vacuum pump by a high suction power

- Strong and error-free sealing

For more information, you can view the vacuum chamber packaging machine page.

Thermoforming Packaging Machine

The thermoforming packaging machine from West Asia Steel Company is used in the packaging of many products, including medical goods. For large-scale packaging of medical equipment, this machine is used by many factories. With this machine, you can automatically package products in flexible or rigid film.

With this machine, it is possible to manufacture containers on the production line in various sizes from film material, automatically load them, and package them using different methods.

The Performance of Thermoforming Machine

The thermoforming machine can package products in plastic containers. The difference between this machine and tray sealers is that the thermoforming machine also manufactures the container. The film is placed in the machine, then formed by the forming mold. In the next section, the packaging is shaped, and finally, it is cut in the last mold.

This machine can be equipped with a UV tunnel and various fillers. After the product is filled into the containers, they are guided to the sealing mold, and if needed, vacuum and gas injection are performed. After this step, the film is sealed onto the container, then cut and exited from the machine.

At the end of the machine, an automatic rower, a jet printer, a traffic table, and even an automatic lidder can be added to complete the packaging line.

If you need production capacity in your desired capacities, you can contact us for guidance on manufacturing a machine with your desired capacity.

Features of the Thermoforming Packaging Machine by West Asia Steel:

- Easy cleaning, stainless steel body resistant to corrosion and oxidation

- Compatibility with various containers and products

- Capability to install various fillers on the machine

- Suitable for filling both diluted and concentrated liquids, multi head fillers

- Ability to install labelers and jet printers on the machine

- Customizable options as per customer requirements

For more information, you can visit the thermoforming packaging machine page.

It should be noted that in addition to medical equipment and supplies, West Asia Steel Company's machines are capable of packaging the following materials:

- Different types of dried fruits, nuts, and dates

- Various types of ready-to-eat cold foods

- Pickled vegetables (such as pickled cucumber, olives) and pickles

- Various poultry, meat, and protein products

- Seafood

- Vegetables, fruits and various types of salads

- Certain dairy products, such as cheese

- Bakery and confectionery

Further reading: Dairy product packaging machines

Important Points Regarding Purchasing a Machine

Purchasing a medical device packaging machine is a crucial and vital subject, and due to its connection with patient health, several important points must be considered. Number of these points are mentioned below:

Standards related to packaging: Ensure that you study and observe the relevant standards for medical product packaging. These standards include international and local standards such as CE, ISO, and FDA.

Variety and versatility: Due to the variety of medical products, the packaging machine should be versatile enough to package all types of products.

Adjustability: Packaging medical products may require different settings due to the varying specifications of each product. Therefore, the packaging machine should have adjustment capability and parametric settings.

Packaging quality: The packaging machine must ensure proper packaging according to the relevant standards to maintain the quality of medical products.

Cost: The price of the packaging machine should be economically justified and acceptable.

After-sales service: Ensuring after-sales service for the packaging machine is highly important. You should ensure that spare parts and after sale services can be provided easily and in the shortest time possible.

Capacity and production: Before purchasing the packaging machine, consider the capacity of your medical products. The machine should be able to package a high capacity of products.

Storage duration: Ensure that the packaging machine can provide suitable packaging to extend the shelf life of medical products.

Transportability: If the medical products are packaged for transfer to other locations, the packaging machine should be capable of packaging them for transport.

Brand and manufacturer: The brand and manufacturer of the packaging machine can guarantee its quality and durability. Reviewing information about the brand and manufacturer, as well as user reviews and recommendations from those who have used similar machines, can help you make an appropriate choice.

Overall, purchasing a medical device packaging machine should be done with thorough accuracy and awareness and it is advisable to consult with experts in this field to ensure you buy the suitable machine.

Price of purchasing medical devices packaging machines

The price of purchasing a medical equipment packaging machine varies significantly depending on factors such as the model and brand of the machine, its capabilities, size, capacity, and other variable factors. Prices can vary greatly for more advanced and larger machines.

The best way to determine the price of a packaging machine is to consult with various suppliers and compare the specifications and prices of different machines. Additionally, you should consider maintenance costs, repair and replacement costs for parts, installation expenses, and training costs. Overall, the purchase price of a medical equipment packaging machine should be carefully determined based on your specific needs.

Price of purchasing a used packaging machine

Similar to other medical devices, purchasing a used machine may come with drawbacks and risks. Some of these considerations include:

- Shorter lifespan: A used medical equipment packaging machine may have a shorter useful life compared to a new machine. This means you may need to repair it or replace it with a new machine in the short term.

- Technical issues: Used machines may have technical issues that could affect the quality of packaging and potentially pose risks such as fire hazards, impacting user sanitary and health.

- Frequent repairs: Used machines often require frequent repairs and technical support, which can lead to additional costs. In some cases, repair costs may exceed the purchase price of the machine.

- Lack of Spare Parts: The parts of used medical equipment packaging machines may need replacement due to wear and prolonged use. Given their age, it is possible that they are no longer covered by after-sales services, and their parts may not be available. This results in reduced quality of repairs, increased costs, and interruptions in your business activities.

- Lack of warranty: Used packaging machines typically do not come with any official warranty, meaning you may not receive any after-sales service from seller or supplier if the machine encounters issues in the future.

- Lack of software updates: Used machines may run on outdated software and operating systems, with limited capability to update to the latest versions. This can reduce the machine's quality and performance.

- Lack of Machine Adjustability and Absence of Special and New Options: Due to the absence of special options and lack of adjustability, it may not be optimal for packaging medical equipment and devices of specific sizes and shapes, and it will likely require manual adjustments.

Therefore, purchasing a used medical equipment packaging machine carries risks that should be considered, and if possible, opting for a new machine is advisable.

Price of a medical devices packaging production line

The price of a medical equipment packaging production line is highly variable and depends on factors such as the type and size of the production line, the number and type of machines, equipment, and machinery needed, the quality of raw materials, and the used technology.

While a simple production line may have lower costs for a small workshop with minimal equipment and support services, more advanced and qualified production lines incur significant expenses.

If you are planning to establish a packaging production line for medical devices, it is advisable to contact different manufacturers and suppliers for consultation. Additionally, consider maintenance, repair, and support costs for the production line, as well as consumable raw materials needed for packaging medical devices.

Purchasing medical equipment packaging machines on installment

Packaging medical devices is a critical process in the medical industry that must be performed with precision and high quality. To purchase a medical equipment packaging machine on installment, you should first contact suppliers and inquire about their installment sale terms.

Many companies offer their customers the option to purchase medical equipment on an installment plan. However, when buying these devices on an installment basis, it is important to carefully review the terms and prices. Before deciding to buy on installments, you need to ensure that the total price of the machine and the installment payment terms are acceptable to you.

Attention should be paid to factors such as the interest rate, the number of installments, the down payment amount, and any special conditions. Additionally, you should ensure the insurance and warranty conditions for the medical devices packaging machine. Finally, before signing the installment contract, you should carefully read and verify the terms and conditions and make sure of their accuracy.

Consultation request for purchase

If you are looking to purchase a medical device packaging machine, it is best to contact our technical experts at West Asia Steel for the best advice. With over 22 years of experience in the field, we have extensive expertise and can guide you in purchasing the best equipment at appropriate prices.

Medical devices packaging machines are highly important as they directly impact the health and satisfaction of patients and the quality of services provided by doctors and specialists. Therefore, selecting the best medical equipment packaging machine for selling your product is very important.

With the expertise and experience of our technical experts, we can provide you with the best advice on purchasing medical devices packaging machines. Please contact us for consultation so that we can guide you in making the right choice.

Comments

Post comment

Comments sent by you will be published after the approval of the website administrator.