The automatic seal vacuum machine (automatic tray sealer) can package food products in plastic trays with high speed, accuracy, and quality automatically and continuously.

This machine automatically and easily loads (transports) the trays into the mold and brings the packaged products out of the machine.

The automatic tray sealer is one of the products designed and manufactured by the talented and experienced engineers of West Asia Steel Company.

After decades of designing and manufacturing complex packaging lines, our technical and engineering department has been able to provide key and complex packaging solutions equipped with various conveyor belts, molds with different shapes, check weigher systems at the input and output, automatic denester, multi-head filler (weighing) machine, fillers for diluted and concentrated liquid, UV tunnel, output conveyor belt, rower machine, and other cases that will be explained below completely.

The speed of this machine by vacuum and injection of gases is 5 to 7 cycles per minute, and in simple packaging is 7 to 8 cycles per minute.

What distinguishes our vacuum and seal machines is flawless performance, high quality, speed, safety, and precision in modified atmosphere packaging, the ability to design custom machines, and integrate them with additional technical components to fully meet customer expectations.

Automatic seal vacuum packaging machines are using for vacuuming air around perishable products like foodstuffs such as pickles, red meat, chicken, fish and … for increasing their shelf life. Automatic machine can perform measuring procedures, filling, vacuum, seal and printing information automatically.

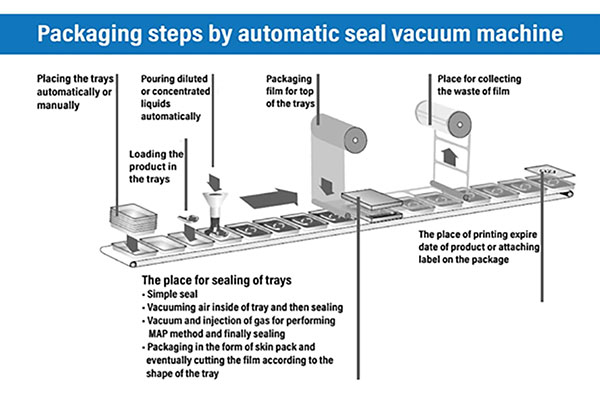

The operation of the machine is as follows:

The automatic tray sealer machine is easily adjustable for different tray sizes to meet the needs of some manufacturers for packaging products. It is only necessary to have a mold for each tray shape so that they can place the relevant mold in the machine during packaging of their product in the desired tray, and after making the necessary adjustments, they can package their product.

The setup and settings of the machine can be easily done by the operator, as the machine is equipped with a very accurate control system and user-friendly software platform, which is both simple and professional. Continuous research on new technologies has helped us to skillfully introduce the automatic tray sealer machine to the market with advanced systems and user-friendly and reliable equipment.

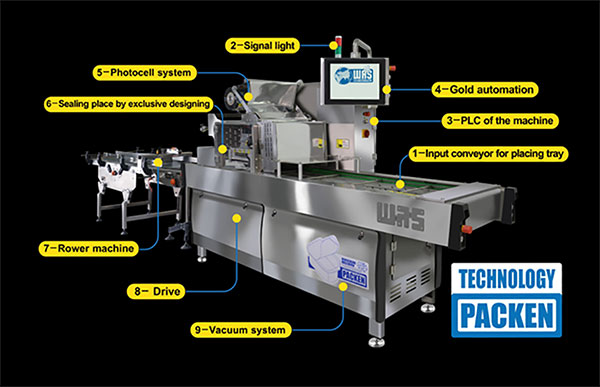

Gold automation is like a complete computer (PC) on the machine and helps after sale services department of this company to solve the problems online, in a way that part of problems will solve by the company with the usage of internet.

The use of the Gold Automation option in the automatic tray sealer machine will have the following advantages:

The engineers at West Asia Steel have designed the automatic tray sealer in such a way that it is easily accessible from all points, making daily cleaning easy.

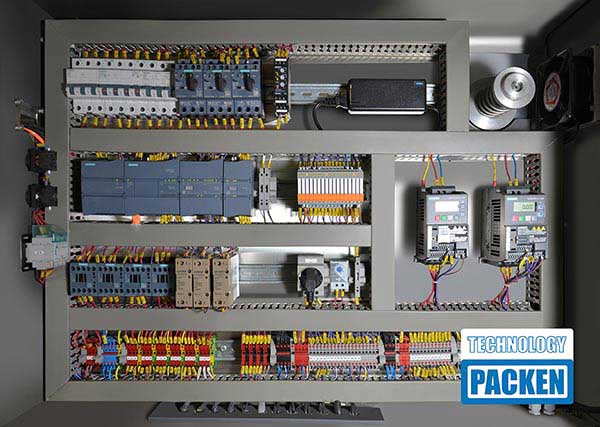

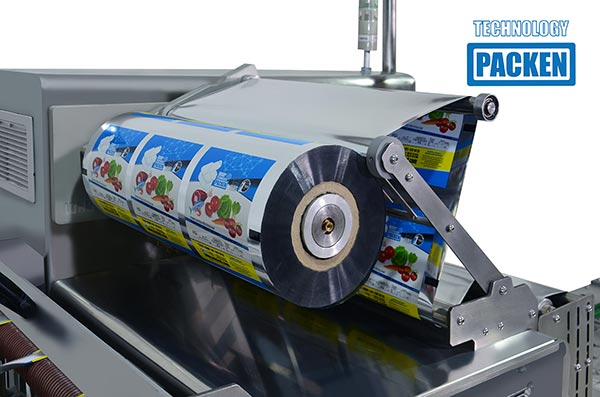

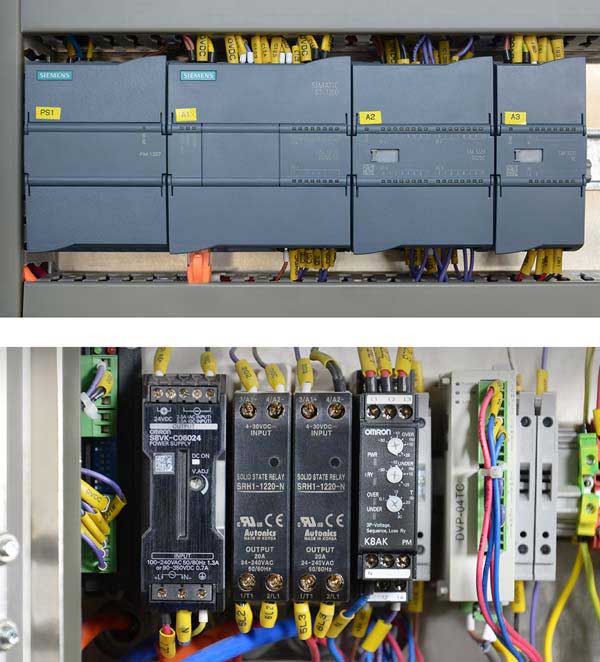

The electrical panel is designed in a completely professional manner and contains high-quality electrical components from reputable brands. Some of these components include:

The electrical panel of the automatic tray sealer is also placed in a way that makes its availability very easy. The appropriate design in this section has made repair and maintenance of the machine and inspect of the electrical panel easier.

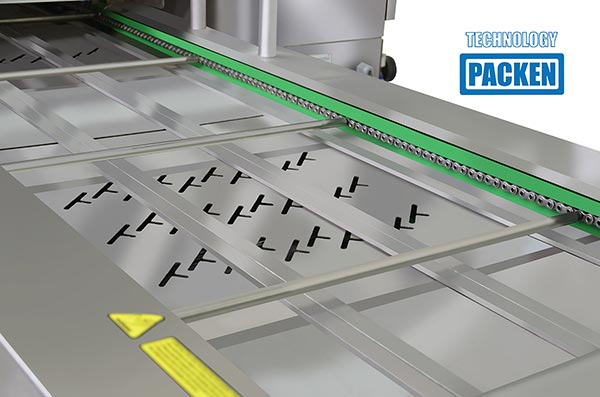

Some features of the mold of this machine include:

The chain rail is made of HP 1000 polymer, which has extremely high resistance to corrosion. This chain is designed and made in a U shape to maintain the chain's movement properly in its path. This has several advantages for customers:

Outlet conveyor is placed in the end of tray sealer packaging machine. This option caused to transfer the products without any error and extra movement after packaging to next part or next machine.

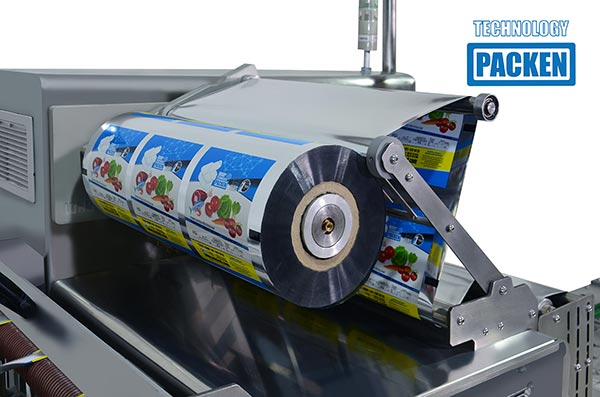

In the right side of the automatic tray sealer machine, a Photocell is placed for packaging food products with printed films, which can be adjusted in its correct position by some parts and has a much lower error rate for determining the correct film position. Unique design, very easy adjustment capability, high-quality sensor, desired number of rollers, and accuracy of film movement in the correct path are among the high advantages of this part.

The advanced sensor of film by intelligent design ensures that the film is perfectly smooth before and after the mold, resulting in more accurate packaging. In this way, the film is sealed onto the tray more beautiful, and packaging is done without default. This part directly contributes to beautiful, wrinkle-free packaging without any problem.

Our unique design in this part ensures that the roll is properly placed and can be used at different widths if needed. This part is designed in a way to be easily and quickly adjustable. The film is placed on an air shaft with locking lugs and can securely hold the film roll and prevent any extra movement.

Changing the roll in West Asia Steel machines is very simple and can be done in the fastest possible way.

This company has a powerful technical and engineering team for programming and automation of automatic tray sealer machines. This team is continuously working on improving the quality of machine programs and always attempts to provide programs without error.

Our goal in developing this group is to increase the quality, level of technology, accuracy of sensors, and parts of precised tools in our products.

The high safety of the automatic tray sealer machine prevents potential hazards for the operator. Number of the functions which were done to increase safety include:

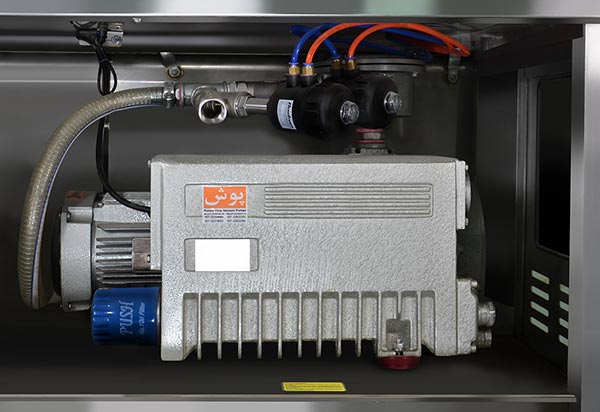

The tray sealer machine of this company is equipped with a powerful vacuum pump and suitable valves for controlling the vacuum process properly. The volume of pump's suction is 63 cubic meters, which increases the number of machine cycles per minute, allowing for more accurate and faster packaging of products using the MAP method. The speed of the tray sealer machines in West Asia Steel by modified atmosphere packaging (MAP) is high.

The pneumatic system of the automatic tray sealer machine of this company is very powerful, calculated, and designed.

Electromtors from the Iranian Electrogen brand and gearboxes have been selected with high quality to have a long life and to produce accurate movements in the machine with high precision.

The bearing system is without error and has qualified parts and plated and metal sprocket (ST37).

Considering the great variety that exists among food products, for example: storage temperatures, microbial flora and different respiration rates, etc., the packaging technology of each product must be carefully selected.

The modified atmosphere technology of automatic seal vacuum (tray sealer) machines can increase the shelf life and quality of the product by changing the natural air composition inside the packaging. In this technology, the percentage of O2, CO2, and N2 gases is adjusted according to the composition of the food material in the packaging, so that the shelf life of the product increases significantly.

This technology is used in the manufactured machines of the Knowledge-Based West Asia Steel Company in a completely professional manner and is one of the most important features of the packaging machines of this company.

The procedure of this technology is as follows: a part of the air inside the tray that has reached the mold of the machine is sent out (vacuum), then a gas suitable for the product is injected into the tray, and ultimately, the film is sealed on the tray so that the modified atmosphere inside the tray remains. The combination of this method, which is vacuum and gas injection (MAP), is the most important technology used in automatic tray sealer machines.

This packaging operates by controlling of the product's respiration rate inside the package (EMAP technology). Oxygen is supplied to the package through micrometer-sized holes, and excess carbon dioxide is sent out. Eventually, this method can significantly increase the shelf life of products such as fruits, vegetables, and salads.

In this type of packaging, the product is secure only toward physical contacts and mechanical effects.

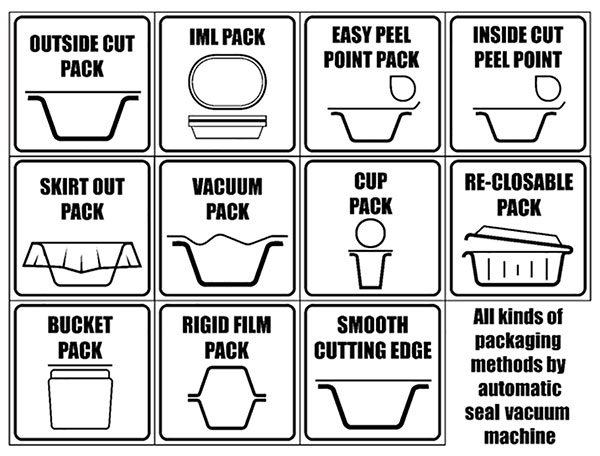

Vacuum Packaging is one of the common methods. After being placed inside the tray, the product is packed by a vacuum that causes the atmosphere to send out of it.

Inside-cut packaging makes the film have no borders around the tray and the beauty of the packaging increases significantly.

West Asia Steel is the only company in the country that can provide customers an automatic tray sealer packaging machine by capability of packaging using inside cut method.

Outside cut pack is the most common type of packing. In this case, the film is cut at a distance of 2 to 2.5 mm from around the tray and then it is sealed on the packaging tray.

This type of packaging is used for products that requires the film to be easily peeled off the tray during consumption. Therefore, the tab created by this method can greatly makes this task easier.

This type of packaging is used for products which film should not open during consumption (specially products which should export or send to other cities, in other words packages should place on each other for a long time).

Packaging food products using the in-mold labeling (IML) method can create a unique beauty. IML trays have labels molded into them during manufacturing. These trays have narrow edges, so their packaging must have special technology.

The vacuum packaging method is one of the common methods. After the product is placed inside the tray, it is packaged by vacuuming (sending out) the atmosphere from inside of the package.

This method (Skirt out pack) is used for cup trays. After packaging, the film is placed in a skirt shape around the tray.

This packaging method is a combination of the Peel Point and Inside Cut methods. In this method, the film is cut inside the edge of the tray and then a tab is created next to it to make it easier for the consumer to peel the film of the tray.

Products which need to be placed inside a bucket are packaged using this method (Bucket pack). Usually, buckets have a high height.

Packaging of cup trays by outside cut is done by this method.

Skin Pack packaging is one of the most attractive packaging methods in the industry. In this method, the product is vacuum-sealed to reduce biochemical degradation due to sending the air from inside of package. After packaging, the product is securely placed in its position and all surfaces of the product are covered with a film.

Different types of skin packaging by considering the shape:

One of the packaging methods for improving product sales is Hanging Pack packaging. After packaging, the trays are hung on store shelves for better showing to customer.

For packaging trays with very narrow cut width, the Smooth Cutting Edge packaging method can be used.

The automatic tray sealer machine is used to package food products in plastic and aluminum trays. In this machine, loading the trays into the mold and moving out the packaged trays from the machine is done automatically and completely easy. In addition, this machine can be equipped with an automatic denester and filler.

In this machine, it is not needed to use operator, and opening the trays from each other and loading them onto the machine is done automatically and continuously. The great advantage of this machine is the fast change of its mold for trays with different sizes. Also, its accuracy in separating the trays from each other without errors is one of its superior features.

Viewing the product: Denester

The technical standards observed to in this machine ensure the following benefits during its usage (product packaging), provide these achievements for manufacturers.

UV tunnel is a fast, chemical-free, cost-effective, and environmentally friendly method which purifies surfaces from harmful bacteria, viruses, fungi, and yeasts.

UV tunnels are ideal for sterilizing surfaces. This machine is used in the food industry to sterilize trays. Removing microorganisms from trays and reducing microbial load has a direct impact on increasing the shelf life of food products. UV tunnels can be installed at the entrance of automatic machine before filler.

Observing the product: UV Tunnel.

The single-to-multiple row converter machine is responsible for consolidating multiple rows into one row or separating one row into multiple rows.

Observing the product: Single to Multiple Row Converter and Vice Versa.

When products are in the form of diluted liquids, concentrated liquids, heterogeneous semi-solid materials, or granulated solid products, filling the product into trays can be done automatically and continuously by these machines, eliminating the need for labor and preventing contamination, are among the most important advantages of using these machines. Additionally, with settings on the machine, the amount of product that needs to be filled into the trays can be controlled and then packaged easily.

Viewing the product: Filler for concentrated liquids.

Viewing the product: Diluted liquid filler

Viewing the product: Volumetric filling machine

Viewing the product: Multi-Head weigher

The automatic rower is placed at the output of the automatic machine after the outlet conveyor belt and put the trays in rows. In the next step, a jet printer or labeler can be installed. The jet printer can imprint the date, price, and production specifications on the tray, and the labeler has the ability to stick labels on packaged trays. These are characteristics of this machine: washable and hygienic standards.

Viewing the product: Automatic row aligner

It is adjustable for different shapes of lids and can be installed at the output of the machine to place lids on trays automatically, eliminating microbial load when placing lids on them manually.

Viewing the product: Automatic lid placer

The rotary table is placed at the end of the packaging line for gathering packaged trays. The table is made of high-quality and washable 304 stainless steel.

Viewing the product: Traffic table (rotary table)

The application of metal detectors is to detect metals inside any product, such as pharmaceuticals and food products. There is always the possibility of accidental existence of metal contamination in products, and in such cases, metal detectors are used as a control system. Therefore, metal detectors play a very important role in the quality control system of packaged products.

Viewing the product: Metal detector

Check weighers are used to control the weight of products. If the weight is less or more than your desired amount, the package will be automatically removed from the line. These machines are placed at the input and output of the tray sealer (seal vacuum) machine. They also have the capability to calculate the price of the product based on its weight automatically and transfer the data to a jet printer for instant price imprinting on the packaging.

Viewing the product: Check weigher systems

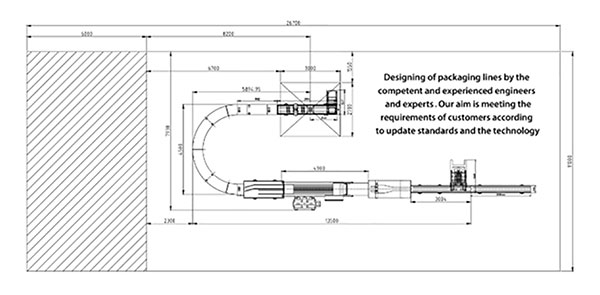

West Asia Steel Machinery Company can design packaging lines according to standards and the requirements of customers. This task is done by the competent and experienced engineers and experts of this company with the aim of meeting the requirements of customers.

Comments sent by you will be published after the approval of the website administrator.