Introduction

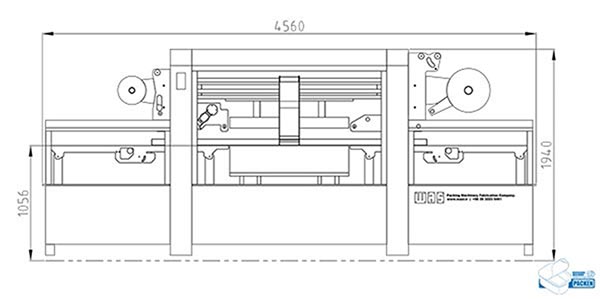

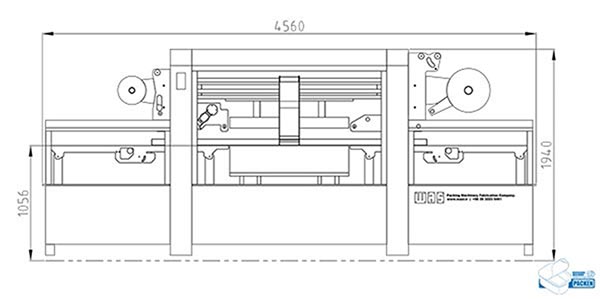

A high-speed tray sealer with 5 times packaging capacity more than automatic tray sealer (seal vacuum) machines and unique performance can package products. This machine is a very good choice for packaging of food products by high-capacity.

The high-speed automatic tray sealer machine is used for packaging food products in plastic trays. Packaging can be done with or without the MAP (Modified Atmosphere Packaging) method. In this method, the packaging of the product is completely automated from receiving the trays to the moving the packaged trays out of the machine.

The high-speed Tray Sealer can reach up to 20 cycles per minute (more than three times compared to general type of automatic tray sealer). This include the machine in the high-level technology category.

This machine offers the possibility of customizing and integration with denesters, fillers, and related equipment. With two decades experience in designing and manufacturing different packaging lines using tray sealer machines, our technical and engineering department is capable of providing key and practical packaging solutions equipped with various conveyors, automatic denester, UV tunnels, various fillers, automatic lidders, automatic rowers, jet printers, traffic tables, etc.

Our continuous research about new technologies and following improved packaging methods have led to the manufacturing of a multi-purpose machine with advanced technical features.

This machine is a full automatic mechanical model designed to ensure high performance and is engineered to allow easy access to all its parts, facilitating cleaning operations. This enhances ease of usage and ensures effective disinfection throughout the entire machine. Prominent features of this machine include easy separation and mold change, which can be done without the need for additional tools.

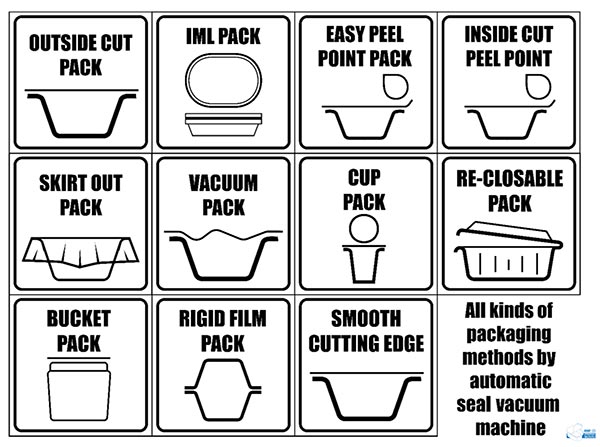

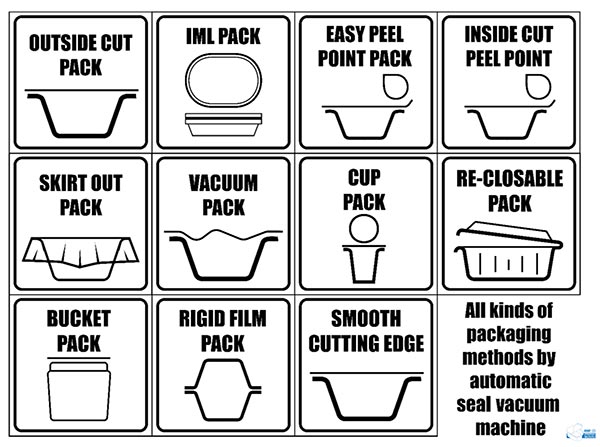

Types of Packaging Methods by High Speed Automatic Tray Sealer

- Inside Cut. Packaging using the Inside Cut method, or cutting from the inside, ensures that the film has no edges around the tray, resulting in a significantly enhanced packaging beauty.

- Outside Cut Pack. This method of packaging is the most common type of packaging. In this case, the film is cut from 2 to 2.5 mm from around the tray and then packed on the opening of the tray.

- Natural Atmosphere. Packing with natural atmosphere method, in which case the product will only be safe against physical contact and mechanical impacts.

- MAP Technology. The modified atmosphere packaging method, which causes the atmosphere inside the package to be modified by the specified gas composition and finally the shape, color and freshness of the product to be preserved for a specified period of time. Carbon dioxide, nitrogen and oxygen gases are usually used to correct the atmosphere inside the packaging.

- IML Pack. Packaging food products in IML trays can create a unique beauty. IML trays are labeled during production. These types of trays have narrow edges, so they should be packaged with special technology.

- EMAP Technology. Packaging by controlling the respiration rate of the product inside the package, which is removed through micrometer holes, provides the necessary oxygen inside the package and removes excess carbon dioxide. This method can ultimately extend the shelf life of products such as fruits, vegetables, and salads.

- Easy Peel Point Pack.This type of packaging is used for products that the film should be easily removed from the tray opening during usage. Therefore, the tab created by this method can help to do this more easily.

- Hard Peel Point Pack. This type of packaging is used for products that require the film not to be easily removed from the tray during consumption. This type of packaging is done when the product is intended for export to other countries.

Skirt Out Pack. This method is used for round trays. After packaging, the film is placed in a skirt-like shape around the tray.- Vacuum Pack. This type of packaging is among the common methods. After placing the product inside the tray, packaging is done by vacuuming, which sends the atmosphere out of it.

- Cup Pack.Packing of round trays is done by outside cut method.

- Bucket Pack. Products that must be placed in buckets should be packed by this method. The buckets usually have high heights.

Top of Form

- Skin Technology. Packaging with the skin pack method is one of the most attractive packaging techniques in this industry. In this method, the product is vacuum-sealed to reduce biochemical degradation due to the sending out the atmosphere out of the package. After packaging, the product is securely placed in its position, and all surfaces of the product are covered by the film and the film is adheres completely to the product.

Packaging by the skin method includes following types:

(Low) Skin packaging for products which after placing inside the tray, are either in the same level with the tray's opening or extend up to 2 centimeters above the tray's surface.

(Medium) Skin packaging for products that after being placed inside the tray, extend approximately 4 centimeters above the tray's surface.

(High) Skin packaging for products which, after placing inside the tray, extend up to approximately 8 centimeters above the tray's surface.

Hanging Pack. One of the packaging methods to help improving of product sales. After packaging, the trays are hung on store shelves for better visibility to customers.

Smooth Cutting Edge. This method is used for packaging trays with very narrow seal width.

Advantages of the Machine:

- The machine is designed in such a way that different parts of it are easily accessible for repairs, maintenance, and cleaning.

- The electrical panel of the machine is positioned for easy access. Proper design in this area makes repairs, maintenance, and panel inspections easier.

- Qualified components are used in the electrical panel of the machine.

- The machine's PLC is from the Siemens brand along with relevant modules.

- Terminals are from the Raad and Pressure brand (resistant to vibration and loosening).

- Contactors and thermal keys are from the Muller Germany or Siemens brand.

- Power supply and phase control are from the qualified Omron brand.

- SSR relays are of superior type and from the qualified Autonics brand.

- PLC relays are from the PHOENIX brand.

- Other parts are from reputable brands available in the market.

- It has precise motion systems along with servo motors for guiding trays into the mold and out of it.

- It features a servo motor system with precise and powerful gearbox for mold movement.

- It includes a servo motor for film collecting to ensure precise movement and prevent film tearing and deviation.

- It has a stainless steel 304 frame resistant to corrosion and oxidation.

- Easy repairs, maintenance, and washability.

- High efficiency, long lifespan, energy efficiency.

- Ergonomic and user-friendly design.

- Capability to order with additional molds.

- Enhancement of beauty and improvement of packaging by tray sealer packaging machines from West Asia steel Machinery Company.

- Customization possibilities and use of different auxiliary machines in the production line.

Various Parts of the Machine

Golden Automation (PC panel) with Remote Maintenance Capability

This option functions like a complete computer installed on the machine, providing the company's after-sales service team with the ability to online troubleshoot. This allows for the resolution of some issues entirely remotely.

- Remote machine communication via the internet for troubleshooting (anywhere).

- Features a highly professional program with qualified graphics for quick and easy machine settings.

- Very user-friendly interface.

- Equipped with a powerful processor for running heavier programs.

- Perfectly suitable for automatic machines equipped with various options.

Input and Output Conveyors

- There are several conveyors at the input and output sections of the machine, which precisely guide containers onto the machine.

- These conveyor belts are designed in a way that they have very simple maintenance and repair requirements.

- Also in their design washability is one of the most important issues that has been observed.

- Some of these conveyors are moved by a servo motor, so they are very accurate and their speed can be set.

- The intelligent design of these conveyors helps to increase the accuracy of the machine a lot.

Gas Control Vessel

This option is used for accurate control gas pressure. In the machine, when the MAP method is carried out, despite this option, gas injection is performed more precisely.

Mold of the Machine

- By casting and machining mold, which leads to the implementation of modified atmosphere packaging with high precision.

- By high resistance of mold toward corrosion

- The design is done in a way that due to the large size of the mold and having many details, the function of the mold is done correctly, its depreciation is low and most importantly, the noise of the mold is negligible.

- The silicone strips placed on the mold parts have a good design and qualified materials, and they are located completely standard and principled in their place.

- The base plate of the machine has a unique design and can cover possible errors.

- With qualified 304 steel pins and qualified phosphor bronze bushes for the smooth and correct movement of the pins into the bushes (This feature shows its importance in the long time.)

- The elements of the mold are in a way that they can create the temperature well and keep the relevant surface hot with a specific temperature.

- The thermocouple in the mold has high accuracy and is installed in a suitable place to determine the temperature of the mold correctly.

- The blades have a separate system, the profile of the teeth is well calculated and made, and they are placed on the mold in such a way that the temperature of the mold does not have a direct effect on them and they perform the cutting process correctly.

- Since our knowledge and experience in the field of mold design is very high, so we can have the least error in mold design.

- The capability to work on all kinds of trays with different shapes, without restrictions

- Coating the aluminum parts of the machine

- Mold changing is done in the shortest possible time, and the machine system is designed in a way that this part is not damaged during the mold replacement.

- Mold transportation is very easy and fast, because a trolley is provided with the machine so that it can be moved easily.

The Frame of the Machine

- Strong structure

- It has sheets by high thicknesses

- By low vibration

- Resistant to loss of accuracy over time

- Completely made of 304 steel, scratched and shiny steel with high beauty, resistant to corrosion and discoloration due to contact with food and detergents.

- The pollution in this type of steel (glossy scratched steel) stays less on it and is easier to wash.

- Designed by international standards and technical and engineering principles

- Easy to wash

Positioning system of printed films - cellophane spot sensor (photocell)

On the right side of the machine, parts have been designed to easily set the photocell for packaging food products with printed films to its correct position and to minimize errors in placing the film correctly on the tray.

The unique design with extremely easy setting, coupled with a qualified sensor in this section, the presence of numerous rollers in this area, and the accuracy of the film movement along its correct path are its notable advantages.

Required Setting System for Film Tension:

- An advanced film tension system with a principled design and specified standards.

- This system ensures that the film is completely smooth and taut before and after entering the mold, allowing it to be placed in the mold and ultimately sealed.

- The presence of this system ensures that the film is sealed onto the tray more beautifully, resulting in packaging without error.

- This aspect directly affect attractive packaging, without wrinkles and without any issues.

Placement of the Film Roll:

- Our unique design in this area ensures that the roll is properly positioned. This section is designed in a way that allows for easy and quick setting if the customer needs to use rolls of different widths.

- We have used an expanding shaft in this section, which has adjustable lugs and can securely hold the film roll while preventing any unnecessary movement.

- Replacing rolls in our machines is very simple and can be done in the fastest possible manner.

Qualified Push Buttons and Switches with Reputable Brands:

- Equipped with push buttons and switches from the Müller brand, along with special silicone covers from the mentioned brand.

- Offers high safety for the operator during machine usage and is easily washable.

- Features qualified emergency switches from the Müller brand, ensuring a long lifespan.

- The main switch of the machine is from the Siemens brand, providing high safety standards.

Professional Programming and Automation System:

- High accuracy of sensors and parts of accurate tool.

- This company has a technical and engineering team dedicated to programming the machine. Our team is constantly working on machine programs and always attempt to provide error-free programs.

- We continuously speak with our customers and gather feedback from them regarding the use of the machine during the packaging process, as our approach is to enhance the quality and technology of our products.

PID System for Controlling the Temperature of the Machine

- Very high quality and excellent material

- Equipped with a PID system for accurate temperature control and ultimately achieving uniform and proper sealing (without wrinkles and without weak seals during packaging)

- The presence of qualified thermocouples, ensuring greater accuracy during packaging and temperature control of molds without error

High Safety System

The high safety system of the machine prevents life-threatening hazards for the operator.

Top of Form

- The presence of emergency button push in various parts of the machine for emergency stopping the machine

- Designing systems to prevent potential errors until the operator is actively working on the machine ensures that no damage comes to them, ultimately ensuring high safety and security for the machine.

- Accurate control of torques in the machine, facilitated by automation and accurate programming within the machine.

- The presence of a tower light to indicate the status of the machine.

- The absence of sharp and vulnerable edges ensures the safety of the operator on the machine.

- Utilizing intelligent design in the machine and placing various parts correctly in their designated positions.

- Using suitable and qualified materials for the parts.

Vacuum System and Vacuum Pump:

- All connections, pipes, and hoses are equipped with good waterproofing to ensure proper air suction and discharge from inside the mold.

- Equipped with a pneumatic system by standard design, allowing for the quick opening and closing of the vacuum path and increasing the machine's speed.

- The machine features a powerful vacuum pump with a suction volume of 160 (one hundred and sixty) cubic meters, increasing the number of cycles per minute and ensuring accurate and faster packaging of products using the MAP method. Therefore, our machines are highly efficient for packaging using the Modified Atmosphere Packaging (MAP) method.

Powerful Pneumatic System

The pneumatic system of this company's automatic tray sealer machine is robustly calculated and selected for its high power.

- The fittings of the machine are chosen from reputable brands to ensure they do not leak over time.

- Large-diameter pneumatic hoses are selected to be compatible with the sizes of valves and jacks.

- The pneumatic circuit of the machine is engineered with accurate technical calculations, prioritizing only good performance quality in its design, rather than opting for cheaper alternatives.

Motion Systems:

- Error-free bearing systems with qualified parts.

- Bearings have a long lifespan.

- Parts ensure correct and accurate movement.

- Adjustable speed capability for different parts.

Automatic Denester

In this device, human touch is eliminated, and the moving the trays from inside of each other and loading them onto the machine is done automatically and continuously. A significant advantage of this machine is its ability to quickly change molds for trays of different sizes. Additionally, its accuracy in separating the trays from each other without errors adds to its superiority.

UV Tunnel

UV tunnels are ideal for sterilizing surfaces. These machines are used in the food industry to sterilize trays. Cleaning trays from microorganisms and reducing microbial load has a direct impact on increasing the shelf life of food products. The capability of installing a UV tunnel at the entrance of an automatic filler exists.

Single to Multi-Row Converter and Vice Versa

In some cases, trays are filled either by specialized fillers or by multiple fillers, and it is necessary to fill them individually or in multiples. In this case, this machine can set the rows according to the production line.

Fillers

Fillers can be in the following forms:

- Multihead filling machine (filler for granular products)

- Filler for powdered products

- Gravity fillers (filler for diluted liquids)

- Piston cylinder filler (filler for concentrated liquids and semi-solid heterogeneous products)

When products are in the form of diluted liquids, concentrated liquids, semi-solid heterogeneous materials, or granular solids, filling the product into trays can be done automatically and continuously by these machines, eliminating labor and preventing contamination. One of the most important advantages of using these machines is their ability to control and package the amount of product that needs to be filled into trays easily through settings on the machine.

Fillers come in several types:

- Piston Cylinder Filler: This machine is used for food products such as honey, jam, mayonnaise, sesame cream, breakfast chocolate, and date syrup. It can be equipped with a heater and mixer in its tank to prevent clogging at the connection for products that may solidify and change viscosity during filling.

- Gravity Filler: This machine is used for filling various diluted liquids into different trays, such as mineral water, yogurt, flavored drinks, and products with viscosity similar to water. The operation of the diluted liquid fillers, also known as gravity filler, is based on the gravitational force of the product, without the need for a pump or motor.

- Volumetric Filler: Volumetric fillers are used for filling various products that cannot be filled into containers by a weighing filler due to their shape and texture. In such cases, this type of filler is used. Among the products that can be filled into containers by this filler are pickled olives and fruit salads.

- Multi-head Weigher: This type of filler is used for products that are granulated. Products such as dried fruits, nuts, legumes, grains, vegetables, nuggets, falafel, and small pieces of chicken or red meat are among the products that can be filled into trays through this method. In general, this machine is used for any product whose accurate weight in packaging is important. The weighing filling machine is one of the most accurate and widely used fillers among filling machines, using a highly accurate weighing mechanism. This type of machine is equipped with very precise and sensitive scales that weigh the product with the least amount of weight tolerance.

- Automatic Rower: The automatic rower is placed at the output of the automatic machine after the outlet conveyor and put the trays in rows. In the next step, a jet printer or labeler can be installed. The jet printer can imprint the date, price, and production specifications on the tray, and the labeler has the ability to stick labels on packaged trays.

- Automatic lid placer: It can be set for different shapes of lids and can be installed at the output of the machine to place lids on trays automatically, eliminating microbial load when placing lids on them manually by operator.

- Traffic Table (rotary table): The rotary table is placed at the end of the packaging line for gathering packaged trays. The table is made of qualified and washable 304 stainless steel.

- Metal Detector: The application of metal detectors is to detect metals inside any product, such as pharmaceuticals and food products. There is always the possibility of accidental existence of metal contamination in products, and in such cases, metal detectors are used as a control system. Therefore, metal detectors play a very important role in the quality control system of packaged products.

- Check Weigher Systems: Check weighers are used to control the weight of products. If the weight is less or more than your desired amount, the package will be automatically removed from the line. These machines are placed at the input and output of the tray sealer (seal vacuum) machine. They also have the capability to calculate the price of the product based on its weight automatically and transfer the data to a jet printer for instant price imprinting on the packaging.

Designing Packaging Lines Using Tray Sealer Machines according to Customer Space

Designing packaging lines is carried out by the technical and engineering department of Steel West Asia Machinery Company, utilizing skilled and experienced engineers and specialists with the aim of meeting customer demands in accordance with standards and requirements stated by them.