The manual tray sealer packaging machine is used for packaging various food products in plastic trays. Due to its small dimensions, this machine is widely used in supermarkets, workshops, and household packaging. In this machine, placing the trays into the mold, picking up the packaged products from the machine, and applying pressure to seal the film onto the tray are done manually by the operator.

It is possible to manufacture molds for trays with different shapes and dimensions for the manual tray sealer packaging machine, but there is not the possibility of changing the mold in this machine.

For example, the capacity of the machine for trays with a size of 17*22 is 150 packs per hour.

The manual tray sealer packaging machine has the capability of package plastic trays using various types of films (plastic film, metallized film, aluminum film, breathable film, and anti-fog film) with different thicknesses, materials, and widths.

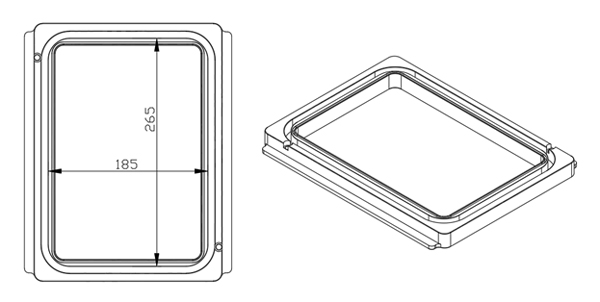

The largest dimensions of the tray that can be packaged with this machine are as follows:

The trays filled by the operator are placed inside the mold, and the film is manually pulled over the tray. Finally, the lever of the machine is guided downwards by the operator, and packaging is done..

Installations and setting the machine is done easily by the operator, and working with the machine is very easy.

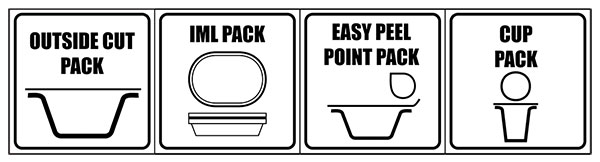

The outside cut packaging method is the most common type of packaging. In this method, the film is cut 2 to 2.5 millimeters away from the edges of the tray, and then it is sealed onto the tray.

Packaging food products in IML (In-Mold Labeling) trays can create a unique beauty. IML trays are labeled during production. These types of trays have narrow edges, which require special packaging technology.

Packaging round trays using the Outside Cut method is done using the Cup Pack technique.

The frame of the machine is made of Taiwanese 304 stainless steel, and the rollers are made of qualified 304 stainless steel. They are highly resistant to corrosion and do not undergo color changes when contacting with food or detergents.

The mold of the machine is professionally manufactured, and the sealing occurs accurately on the edges of the tray. The mold is equipped with two standard pressure elements to reduce pressure.

Comments sent by you will be published after the approval of the website administrator.