Biscuit is one of the most important products made from flour, which due to its ease of preparation, storage, and consumption, has gained widespread popularity. Therefore, appropriate and proper packaging of biscuits, in addition to ensuring the sanitary of the product and protecting it from contamination, also leads to increased sales. Biscuits are packaged using various methods and are supplied to the market.

One of the companies manufacturing biscuit packaging machines is West Asia Steel Company, which specializes in the manufacturing of packaging machines. This company is dedicated to manufacturing packaging machines for various products with the aim of customer satisfaction. In this blog, we will investigate biscuit packaging machines and their operation methods. Join us and don't miss out on this useful article for a better understanding of biscuit packaging methods.

The Most Important Reasons for Packaging Biscuits

Biscuits are one of the food products with high susceptibility to powdering, so attention to their packaging is crucial. Below are the most important reasons for packaging biscuits:

Protecting Biscuits from Contamination: All food products are susceptible to contamination from pollutants and bacteria. However, products that undergo longer periods of transportation or storage are at a higher risk of contamination. Therefore, proper and uniform packaging is crucial. Food manufacturers take quality control measures very seriously in their food packaging programs, using leak testers to ensure the consistency of packaging. Faulty packaging not only affects the quality and integrity of food products but can also affect consumer health.

- Increased Product Shelf life: Proper packaging can significantly increase the shelf life of a food product. Weak packaging leads to shorter shelf life, which in turn can cause food safety issues. Most people believe that storage of food products in low temperatures improves their shelf life. However, packaged foods still undergo degradation when exposed to oxygen. Additionally, proper packaging can protect products from moisture, as a strong, non-permeable packaging prevents moisture from penetrating in and causing adverse effects, particularly on biscuits.

- Protection against Physical damage: The quality of a food product may be affected by physical damage. Packaging for products like biscuits, which are sensitive to physical damage, should be made of impact-resistant materials, such as sturdy plastic containers, to minimize damage.

- Preservation of Food Freshness: Freshness encourages customers to repurchase a food item. Packaging helps preserve the freshness of a product. Proper use of modified atmosphere packaging methods can significantly contribute to maintaining the quality and freshness of the product.

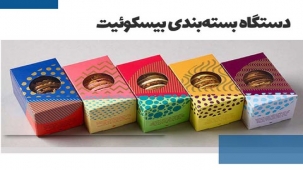

- Marketing: Packaging contributes to the way a product is sold. If the designs, logos, and phrases on the packaging are not appealing, not only will food products not attract attention, but their sales will also decline. Therefore, attention to the attractive appearance, color scheme, and unique shape of the packaging can attract more customers, especially since children often lead the way in purchasing biscuits.

- Protection toward Biological Factors: Packaging helps protect biscuits from microbes, bacteria, insects, and other biological factors.

- Information Labeling: After packaging products, information related to the product, such as brand name, expiration date, storage method, and ingredients, is provided on the product. Product labeling provides useful information about the nutrients in the product, calorie content, etc., to the customer. In packaging done by tray sealer machines, the use of printed films is possible, which not only reduces costs but also enhances the packaging's beauty.

- Ease of Usage: Packaging biscuits in trays makes them easier to store and use.

- Ease of Transportation: Packaging biscuits in suitable trays facilitates their transportation.

What are the Features of Good Biscuit Packaging?

A good biscuit packaging should have the following features:

- Product Information: A good packaging should have product information labels. Customers initially check the price, contents, weight, production and expiration dates, and calorie content of the biscuit product. Therefore, mentioning this information on the packaging influences the customer's decision to purchase the product.

- Attractive Appearance: The first thing that attracts the customer's attention from a distance is the attractive packaging of biscuits. The use of bright and captivating colors tempts the customer to buy the product. Additionally, trays with unique shapes that distinguish you from competitors can significantly impact increasing sales volume.

- Packaging Strength: Customers pay attention to the strength of the packaging when purchasing biscuits because biscuits easily crumble, and improper packaging can lead to damage and ruin the biscuits and their decorations.

- Waterproof Packaging: Since biscuits deteriorate due to moisture, waterproof packaging helps protect biscuits more. Packaging biscuits by Stainless West Asia sealing and vacuum machines keeps them safe from such damages.

- Hygiene Preservation: Maintaining hygiene during food packaging is of paramount importance. Customers buy products that are hygienically approved and have a clean and tidy appearance.

- Recyclable Packaging: Using recyclable materials in packaging production helps increase product sales.

Materials Used for Biscuit Packaging

The following materials are used for packaging biscuits:

- Plastic Trays: Plastic trays come in various shapes and dimensions, are resistant to physical, biological, and moisture damage.

- Plastic Films: Plastic materials with good sealing properties, easy shaping, and lightweight are notable. One of the plastics used in biscuit packaging is polypropylene, which is used to produce thin and transparent films. This type of packaging is susceptible to physical damage and moisture.

- Cardboard and Paper Boxes: Cardboard and paper boxes are inexpensive, easily disposable, and create minimal pollution. This type of packaging is susceptible to some physical damage and moisture.

- Tin Boxes: These packages are notable for their high strength and good sealing. However, the cost of materials and their production is relatively expensive. Also, such packaging needs a large space.

Types of Biscuit Packaging Machines

The machines used for packaging biscuits vary depending on the level of automation and whether the process is for household or industrial use. These machines include the following:

- Semi-automatic Tray Sealers (Seal Vacuum)

- Automatic Tray Sealers (Seal Vacuum)

- Stretch Machines

- Manual Sealers

- Thermoforming Machines

- Horizontal Sealing Machinesm

Sealing Packaging Machine

Tray sealer packaging machines effectively seal plastic trays and prevent moisture and air from entering them. These machines are used for packaging foodstuff and are manufactured in various types, including fully automatic, semi-automatic, and manual. Below, we introduce different types of tray sealer packaging machines.

Automatic Tray Sealer Packaging Machine

An automatic tray sealer packaging machine is a fully automated machine that efficiently packages foodstuff into plastic trays with high speed, accuracy, and quality.

The automatic packaging of biscuits is carried out using the automatic tray sealer packaging machine. The packaging process for biscuits using this machine is explained below:

Pre-made trays are placed onto the machine automatically or manually.

- Biscuits are placed inside the trays automatically or manually, depending on their dimensions and shapes.

- The trays containing biscuits are guided into the machine's mold via a conveyor.

- The trays are sealed ordinary, using vacuum or the Modified Atmosphere Packaging (MAP) method (wherein a film is heat-sealed onto the tray).

- Subsequently, the sealed trays are directed to a jet printer or labeler to print information onto the packaging.

- Finally, the packaged trays are guided towards the traffic table using a conveyor.

Semi-Automatic Tray Sealer Packaging Machine

The semi-automatic tray sealing machine is another machine used for packaging biscuits. It is suitable for producing products in small to medium capacities. The packaging process in the semi-automatic packaging machine with a rotary table (designed by West Asia Steel Company) is as follows:

- Plastic trays are manually filled by the operator.

- Then, the filled trays with biscuits are manually placed onto the machine's mold.

- The table of the machine is rotated by the operator.

- The settings of the machine are adjusted by the operator, and the machine receives the packaging command.

- During the packaging process, one side of the table is outside the machine, allowing the operator to load new trays, which increases the work speed.

- The operator rotates the table again.

- Finally, the packaged trays are moved from the mold upwards by the ejection system.

Thermoforming Packaging Machine

The thermoforming packaging machine is suitable for packaging food and medical products. One of its most important features is packaging using the modified atmosphere method with high accuracy to increase the shelf life of products. The main difference between this machine and a tray sealer is that in this method, the tray is formed, whereas in packaging by tray sealer machines, trays are purchased ready-made. Soft and flexible films as well as rigid films (such as disposable trays) are used in the packaging produced by the thermoforming machine. The packaging process in this machine is as follows:

- Initially, films are placed on the machine to create plastic trays.

- The mold shapes the films to form packaging trays.

- The formed trays enter the cutting mold and are cut.

- Biscuits are poured into the trays using a filler or manually.

- After filling the product into the trays, a conveyor guides them into the sealing mold.

- Vacuuming and gas injection process are carried out at this stage.

- Then, the film is sealed onto the tray.

- After sealing, the trays are cut and moved out of the machine.

- An automatic rower arranges the trays exiting the machine in rows.

- Finally, information is printed on the packaging using a jet printer, and the trays are placed on a traffic table.

Household Biscuit Packaging Machines

Another production machine by West Asia Steel Company is the manual sealing machine. This machine is used for household purposes due to its low production speed and delivers a small numbers of packaging to you throughout the day. Working with this machine is very simple and does not require any special skills. The operation method of the manual sealing machine is as follows:

- Initially, the operator places the biscuits into plastic trays.

- Then, the trays are placed inside the manual sealing machine, and place the film on them.

- After placing the film, the operator pulls down the lever of the sealing machine, and the packaging process is performed.

The Price of a Biscuit Packaging Machine

The prices of packaging machines manufactured by West Asia Steel Company vary depending on the designs, sizes, and different prices. These machines can be customized according to the requirement and preferences of the customer, and any modifications made to the machine will affect its price. Therefore, the final price of the machine depends on factors such as the type of machine, level of automation, speed and accuracy, production capacity, and the use of auxiliary equipment. If you intend to purchase one of West Asia Steel's packaging machines, visit our blog and after selecting the desired machine, auxiliary equipment, and considered options, contact our experts to inquire about the prices of the machines.

Buying the Best Biscuit Packaging Machine

If you're considering setting up a biscuit packaging production line but lack sufficient information about the machines and auxiliary equipment used in the packaging line, visit our blog and explore the various products of West Asia Steel Company. West Asia Steel Company manufactures various types of packaging machines and their peripheral equipment. For years, this company has been designing and manufacturing efficient and qualified machines with an experienced and professional department. The aim of this company is to satisfy its valued customers. So, if you intend to buy a biscuit packaging machine, contact us and take advantage of the guidance and assistance of the hardworking engineers and experts of this company. The technical team of the company shares its experiences with you and provides consultation to help you purchase a machine according to your requirement.

References

pwrpack.com

ift.onlinelibrary.wiley.com

cankey-tech.com

biscuitpeople.com

Comments

Post comment

Comments sent by you will be published after the approval of the website administrator.