Importance of Cold Sandwich packaging

The packaging of foodstuffs has great importance, and this issue affects various aspects of health, hygiene, the environment, and consumer convenience.

The First importance of packaging cold sandwiches is related to preserving the hygiene and quality of this product. Packaging provides a protective layer for the sandwich, preventing direct contact with hands or any external particles, thus preventing the transfer of contaminants such as microbes, dust particles, insects, and other harmful physical factors.

Also, the way sandwiches are packaged contributes to improving their transportation from the point of preparation to the point of consumption. The use of light and break-resistant trays makes transportation easier, allowing consumers to carry their sandwiches easily and without any problem to any location.

Plastic trays are recyclable, and their usage in sandwich packaging can lead to a reduction in the production of non-biodegradable waste and minimize environmental pollution. Also, from an economic aspect, the use of recyclable trays can contribute to reducing the loss of raw materials.

As a result, packaging cold sandwiches in plastic trays not only contributes to improving the sanitary and quality of the food but also helps to prevent microbial contamination, enhances consumer convenience, and contributes to environmental protection.

Cold Sandwich packaging by Modified Atmosphere Packaging (MAP)

In summary, packaging of cold sandwich by MAP is an advanced technology which promotes shelf life and quality of cold sandwiches. This method alters the atmosphere inside the packaging by accurate combination of gases to increase the shelf life of product. The following highlights the importance and advantages of packaging cold sandwiches using the MAP method:

1- Preservation of freshness and product quality: Packaging using the MAP method, with modification the percentage of gases inside the packaging, preserves the organoleptic properties (odor, taste, and color), quality, and ultimately the freshness of the product.

2- Increased shelf life: The MAP method leads increasing the shelf life of cold sandwiches by 2 to 4 times. The absence of oxygen prevents the oxidation process of foodstuffs, consequently extending the product's expire date.

3- Preservation of product texture: MAP helps preserving the texture of the sandwich. This method prevents chemical and physical changes in the food, providing consumers a desirable experience of the sandwich.

4- Preservation of sanitary and health: Preserving the sanitary and health of the consumer is one of the main advantages of this method. Lack of oxygen and environmental microbes decreases the risk of food contamination and the transmitting of diseases.

5- Reduction of food waste: With the increased shelf life of the sandwich, the possibility of food waste is also reduced. This contributes to the economic efficiency of the food production, distribution, and consumption processes.

6- More moderate environmental impacts: The use of the MAP method leads to a reduction in the amount of plastic waste related to packaging since these packaging materials are recyclable, they can significantly contribute to environmental protection.

The packaging of cold sandwiches using the Modified Atmosphere Packaging (MAP) method is performed without fault and by high accuracy with tray sealer machines from West Asia Steel Company.

Totally, packaging cold sandwiches by the usage of the Modified Atmosphere Packaging (MAP) method not only contributes to improving the shelf life and quality of the food but also helps to promote sanitary and health, reduce food waste, and protecting the environment.

How can we increase the shelf life of food products without using chemical preservatives?

There are various natural solutions to increase the shelf life of food products, below, we will discuss ways to preserve cold sandwiches without using chemical substances:

- Selecting high-quality and fresh foodstuffs can increase the shelf life of the sandwich. Fresh ingredients have the lowest levels of bacteria and microbe, contributing to the freshness and health of the food.

- Store the sandwich at an appropriate temperature in the refrigerator. Lower temperatures can delay the growth of bacteria and microbes, thereby increasing the shelf life.

- Hygienic and suitable packaging can protect the product against air, light, and moisture, positively impacting the shelf life of the sandwich. Using packaging materials with preservative properties, such as nano-trays and nanofilms, can also significantly increase the shelf life.

- Another method for extending the shelf life of food products is Modified Atmosphere Packaging (MAP). This type of packaging can be performed using tray sealer machines and vacuum chambers. Initially, vacuum is done, the air inside the package is sent out and subsequently, an appropriate percentage of Carbon dioxide and Nitrogen gases is injected into the packaging. These gases have no impact on the foodstuff itself; they only contribute to increase the shelf life and preserving the organoleptic properties of the product. For cold sandwiches, a typical mixture is often 30% CO2 and 70% N2, though these percentages may vary based on the specific ingredients of the sandwich.

- Vacuum of cold sandwiches can also significantly play an effective role in preserving freshness and increasing the product's shelf life. Because by sending out an appropriate percentage of oxygen, the growth of aerobic microorganisms such as various fungi will delay, and also the product will not encounter reactions such as oxidation.

Increasing the beauty of packaging by tray sealer (seal vacuum) machines

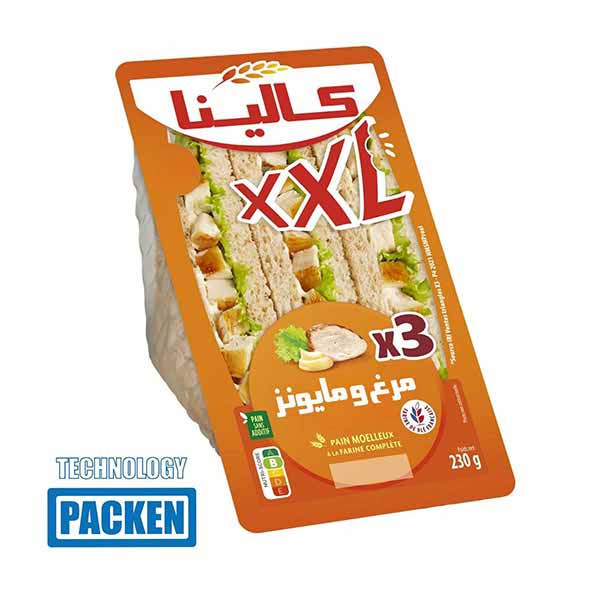

Packaging, as a key element in attracting consumer attention has a significant importance. For promoting the beauty of sandwiches packaging in plastic trays, firstly you should focus on the visual aspects of the product for ensuring that consumers immediately recognizing the product not only excels in terms of quality and sanitary but also in terms of appearance. Subsequently, number of strategies and ideas for enhancing the beauty of packaging of sandwiches in plastic trays will evaluate.

- Utilizing attractive design: Packaging design inspired by appealing and creative graphic aspects can attract consumer. The use of vibrant colors, patterns, and attractive images can enhance the beauty of the packaging.

- Using innovative materials: Choosing innovative and high-quality plastic materials can ensure the beauty of packaging. Materials with high brilliance and transparency or even those with specific forms and structures can increase visual attractiveness.

- Utilizing advanced printing technology: Advanced printing technologies such as digital printing and photographic printing can assist in creating high-quality and diverse patterns and images. These technologies provide printing on various plastic surfaces.

- Using trays with different shapes and colors: Innovative and specific shapes of trays differentiate the product from competitors. Packaging trays with particular shapes can be achieved using trays sealer machines from West Asia Steel Company.

- Promoting visual communication with content: Using attractive images of used sandwich and ingredients can create a stronger visual connection between the consumer and the product.

- Attention to final details: Final packaging details, such as the usage of logos, shapes, and unique patterns, can have a significant impact on the final beauty of the packaging.

Considering these points, enhancing the beauty of the packaging for cold sandwiches in plastic trays not only helps to attract consumer attention but also makes a positive and enjoyable shopping experience, leading to the gain of loyal customers.

The importance of sanitary in the packaging of cold sandwich

Maintaining hygiene should be observed from the beginning of production and processing to the final stage of production, namely packaging. Since the safety of foodstuffs and their healthiness are related to consumer food safety, it has special importance. Without observing sanitary issues in the production, processing, and packaging of foodstuffs, including cold sandwiches, can lead to contamination of the final product and ultimately food poisoning for the consumer.

Due to the use of a variety of raw and cooked ingredients in the cold sandwich, preserving hygiene in the production and packaging of this product is of greater importance. Therefore, it is recommended that operators use hats, gloves, and masks during production, and minimizing human labor as much as possible. In this regard, at the end of the production process: the packaging section, packaging machines can be used which requires the least number of human labor.

Additionally, the use of hygienic and food-grade plastic trays and films has a significant impact on reducing product contamination. To ensure the sanitary of the trays, a UV tunnel from the West Asia Steel Company can be used to sterilize empty trays and eliminate microbial loads. On the other hand, the type of packaging performed and the absence of dripping loss are crucial factors in preventing secondary contamination of the product against external factors such as physical impact, moisture, dust, insects, and biological agents.

Hygienic packaging of sandwiches using safe materials and according to sanitary standards helps businesses align with industrial regulations and safety standards. This helps to maintain the credibility and trust of customers as well.

As a result, sanitary packaging for cold sandwiches not only plays a protective and transportation role but is also significant as a marketing tool and for promoting the consumer experience. This type of packaging can have a significantly positive impact on the development of businesses and customer satisfaction.

Cold sandwich packaging machines

For the packaging of sandwiches, various types of machines are used depending on the chosen packaging type. The following describes the applications of different types of machines:

- Automatic tray sealer (seal vacuum) machine

- Semi-automatic tray sealer (seal vacuum) machine

- Vacuum chamber machine

- Pillow pack machine

- Thermoforming machine

- Manual seal machine

Automatic seal vacuum machine

The automatic tray sealer machine is using for packaging cold sandwiches inside trays with various shapes and high production capacity. The mold of this machine is changeable, allowing the packaging of products in two or more types of trays with different dimensions and shapes and also, by the usage of Modified Atmosphere Packaging (MAP) methods, the machine can increase the product's shelf life without the use of chemical preservatives.

Features of the automatic tray sealer machine from West Asia Steel Company:

- High-capacity packaging

- Customizable with auxiliary equipment (denesting system, UV tunnel, filler, rower, rotary table, etc.)

- Low depreciation

- Standard and hygienic

- High safety standards

- Usable with various films by different materials, thicknesses, and designs

- Firm sealing without error

- User-friendly

- High accuracy in performing the Modified Atmosphere Packaging (MAP) method

Semi-automatic seal vacuum machine

The semi-automatic tray sealer machine is used for packaging sandwiches in trays with lower production capacity. This machine requires an operator to place trays on the rotary table, rotating it, and loading filled trays on the other side of the table.

These seal vacuum machines have the capability to package various plastic and aluminum trays, either using the Modified Atmosphere Packaging (MAP) method or just with vacuum.

Features of the semi-automatic tray sealer machine from West Asia Steel Company:

- Medium-capacity packaging

- Low depreciation

- Mold changing

- Standard and hygienic

- High safety

- Firm sealing without error

- User-friendly performance

- High accuracy in executing the Modified Atmosphere Packaging (MAP) method

Chamber Vacuum Sealer

A chamber vacuum sealer is used for packaging cold sandwiches inside three-sided sealed pouches using vacuum sealing or MAP (Modified Atmosphere Packaging) methods. The vacuum chamber from West Asia Steel is a dual-chamber machine, providing a higher production capacity. This machine is equipped with a 100 cubic meter vacuum pump, allowing it to achieve the highest level of vacuum, ensuring that the pouch or cover adheres completely to the product (adjustable as needed).

Features of the West Asia Steel Chamber Vacuum Sealer:

- Low energy consumption

- Standard and hygienic

- High safety

- Secure and flawless packaging

- Easy to use

- High accuracy in performing the MAP method

- Ability to package various pouches with different materials (plastic, aluminum, and metallized), thicknesses, and designs.

Pillow-packaging machines

Pillow-packaging machines are used for packaging cold sandwiches inside plastic or metallized pouches. Depending on their model, these machines may perform gas injection but packaging by Modified Atmosphere Packaging (MAP) method cannot performed with these machines, as proper performance of this method firstly requires vacuuming, followed by injecting gas into the packaging under vacuum conditions.

Thermoforming machine

The thermoforming packaging machine creates the tray firstly, then the product loads into the tray and in the next step, after vacuum and injection of gasses, a plastic or metallized film is sealed on the tray. This linear machine provides for the use of additional equipment such as UV tunnel, various fillers, and other auxiliary machines, however for products like sandwiches, they need to be manually placed inside the tray, and fillers are not used for such products.

Features of the thermoforming machine from West Asia Steel Company:

- High-capacity packaging

- Customizable with additional machines (deneter, UV tunnel, filler, rower, traffic table, etc.)

- Low depreciation

- Easy cleaning, stainless steel body resistant to corrosion and oxidation

- High safety standards

- Usable with various films of different materials, thicknesses, and designs

- Firm sealing without error

- User-friendly operation

- High accuracy in performing the Modified Atmosphere Packaging (MAP) method

Manual sealing machine

The manual sealing machine is designed in small dimensions for easy usage in supermarkets and homes to package inside plastic trays. The filled trays is loaded by the operator into the mold, and the film is placed on the tray by the operator and lever is then pulled down, and the packaging process is completed.

This machine does not have the capability for vacuum and injection of gasses.

Features of the manual sealing machine from West Asia Steel Company:

- Low-capacity packaging

- Easy cleaning, stainless steel body resistant to corrosion and oxidation

- Standard

- Usable with various films of different materials and designs

- Firm sealing without error

- User-friendly operation

- Without changeable mold

For cold sandwich packaging, which trays can be used?

For packaging cold sandwiches, plastic trays with different colors and shapes can be used. Generally, Polypropylene (PP) plastic trays are commonly used for packaging club sandwiches and various types of sandwiches.

Different plastic trays which can be sealed

- Polyethylene Terephthalate (PET) trays

- Polyvinyl Chloride (PVC) trays

- Polystyrene (PS) trays

- Polypropylene (PP) trays

- Polyethylene (PE) trays

For cold sandwich packaging, sandwich clubs, and various types of sandwiches, films of different materials and thicknesses can be used depending on the material of the tray.

If you have not found the desired shape or dimensions of the tray among the standard products of tray manufacturing companies, you can order your intended mold. Initially, your tray will be designed according to your request, and a 3D printer will gain an initial prototype and after final approval, you can order your mold to tray manufacturing companies. If you have ordered this shape exclusively, no other producer will be allowed to use sample of your trays and your product will be exclusively packaged within trays particular to your brand and will be distinguishable from other brands for consumers.

Types of films for cold sandwich packaging

For packaging of cold sandwiches, sandwich clubs, and various types of sandwiches, films of different materials and thicknesses can be used depending on the material of the tray. Some of these films include:

- Polyethylene Terephthalate Film (PET)

- Polyethylene Film (PE)

- Polypropylene Film (PP)

- Cast Polypropylene Film (CPP)

- Biaxially Oriented Polypropylene Film (BOPP)

- Oriented Polypropylene Film (OPP)

- Biaxially Oriented Polyester Film (BOPET)

- Polyolefin Film (POF)

- Polyvinyl Chloride Film (PVC)

- Metallized Film

- Anti-fog Film

- Aluminum Foils

- Vacuum Chamber Pouches

- Polyamide Film (PA)

The price of a tray sealer machine

The price of stainless steel tray sealer machines from West Asia Steel is dependent on the dimensions of the customer's trays, options, and additional equipment for the machines. For consultation and prices, please contact our experts.

Installment Purchase of tray sealer (seal vacuum) Machines

West Asia Steel, as a knowledge-based company, is ready to provide services to valued customers with special sales conditions for worry-free purchases by manufacturers. For detailed information, please contact our experts.

Sanwich Packaging samples

Comments

Post comment

Comments sent by you will be published after the approval of the website administrator.