The vacuum chamber packaging machine is used to pack all kinds of food products in plastic bags.

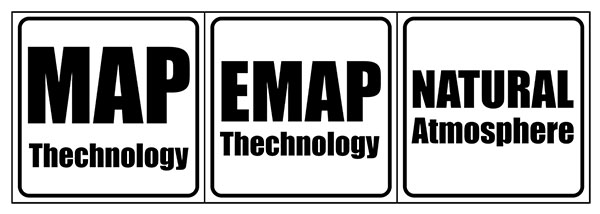

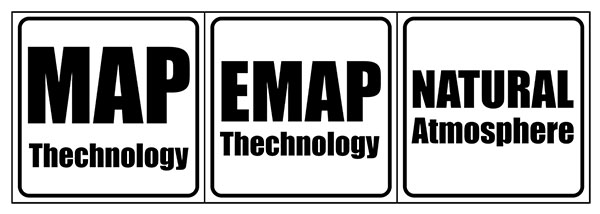

Generally, this machine performs the packaging of products with complete vacuum, but it also has the capability of packaging using the Modified Atmosphere Packaging (MAP) method.

The packaging of products by the Vacuum Chamber Machine can be done through the following methods:

- Full vacuum

- Packaging with modified atmosphere

- Fully vacuum-sealed packaging using special films with Shrinkage properties

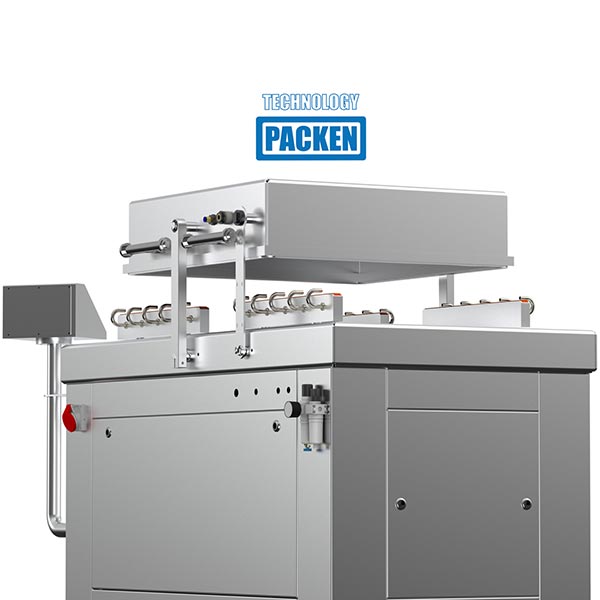

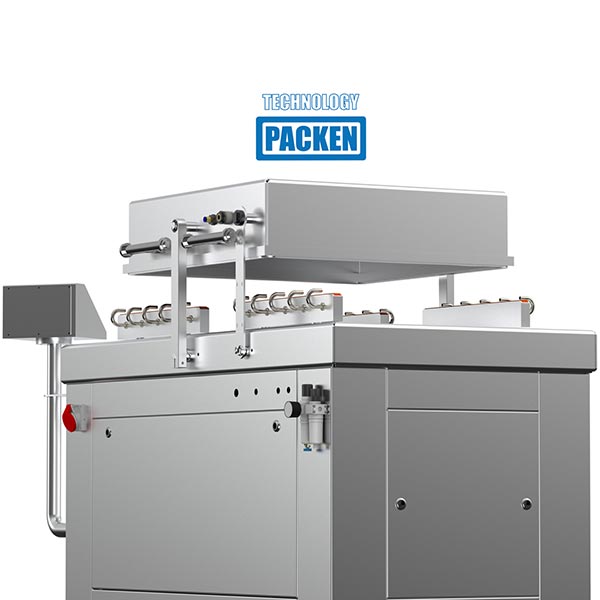

The Vacuum Chamber Machine with two cabins (double chamber packaging machine) is highly efficient and requires small space. The operation of this machine involves manual handling, where plastic bags filled with the product are placed manually in the machine and removed manually after packaging.

This machine is equipped with a PLC and a touch screen HMI for accurate control and easy settings by the operator. The machine has a maximum of 5 packaging programs that can be changed by the operator. Repair and maintenance of different parts of the machine are very easy and meet standard design principles. Various parts of the machine are easily accessible for quick and efficient settings.

Packaging by Various Methods

Packaging using the Modified Atmosphere Packaging (MAP) method is carried out with a certain percentage of vacuum and gas injection, ultimately increasing the shelf life of the product.

Additionally, vacuum packaging is a process which the air includes high valume of Oxygen and Nitrogen in addition of other gases, is sent out from the pouch before sealing completely to incraese shelf life of products which encounter spoilage faster than other products. In this method vacuuming is done in a way that plastic pouch will be adhered to the product completely.

Speed

The machine operates at a speed of 1 to 3 cycles per minute in vacuum packaging manner and 1 to 2 cycles per minute by gas injection packaging.

The Vacuum Chamber Machine with two cabins has the capability to package various plastic and metallized pouches by strong sealing without error.

By utilizing our experts training, relevant practical videos, and guides provided by the company, you can easily set the machine and operate the packaging process without any issues.

- Maintenance and repairs of the machine are easy, and the machine elements are expose to damage are easily replaceable.

- Stong and durable construction

- Accurate and smart system with a high level of safety

- Use of durable and qualified parts

- Very reputable and superior quality compared to other samples in the country.

- On-time delivery.

- Extremely high standards compared to machines available in the market.

- A secure purchase means guidance from expert consultants and increasing your awareness in making the right choice for the machine and required options.

- Availability of a technical and experienced engineering team to provide services and guidance.

- Use of qualified parts in the machine.

- Observing necessary international standards.

- Intelligent design

- Accurate system with high technical and engineering coefficients without error

- Timely and well-planned after-sales services

- The machine is designed in a way that the sealing during the vacuum process occurs in the best possible manner.

Types of Packaging Methods

Modified Atmosphere Packaging (MAP Technology). The modified atmosphere packaging method, which causes the atmosphere inside the package to be modified by the specified gas composition and finally the shape, color and freshness of the product to be preserved for a specified period of time. Carbon dioxide, nitrogen and oxygen gases are usually used to correct the atmosphere inside the packaging.

Natural Atmosphere. Packing with natural atmosphere method, in which case the product will only be safe against physical contact and mechanical impacts.

Packaging by Equilibrium Atmosphere (EMAP). Packaging with the Equilibrium Atmosphere or EMAP method is a technic where the required oxygen inside the package is supplied through micrometer-sized holes, and excess carbon dioxide is sending out. This method can ultimately increase the shelf life of products such as fruits, vegetables, and salads.

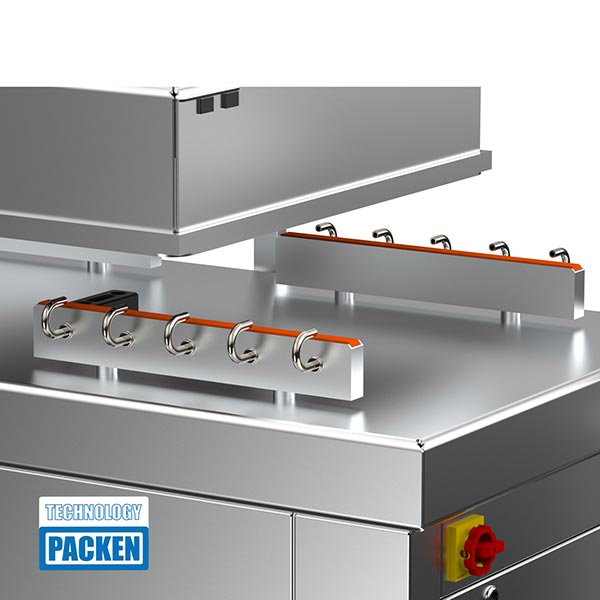

Introduction to Various Parts of the machine

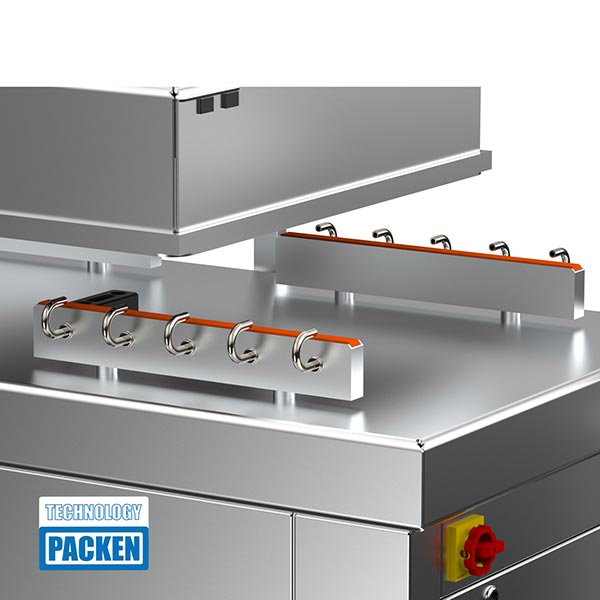

Chamber or Cabin of the Machine

- Chamber Dimensions: Length 60 centimeters - Width 50 centimeters - Height 15 centimeters

- The machine has two cabins to reduce the time for loading and packaging the product.

- Washable

- The coil system and the cabin's movement are professionally designed for easy movement and setting.

- The elements are designed smartly to provide effective sealing. Additionally, their maintenance and repairs are easy.

Touch control panel of the machineTop of Form

- 2-inch HMI touch screen from the qualified Delta brand.

- Temperature, vacuum percentage, gas injection, pressure, and many other settings are performed by the touch screen.

- Supports both English and Persian languages.

- This machine is equipped with PLC and an HMI touch screen to ensure accurate control and easy setting of the machine by the operator.

- The machine can store up to 5 packaging programs, which can be easily changed by the operator.

- Fully intelligent packaging method.

Seal section

- Length: 500 mm (50 cm)

- Standard dimensions of the bag: In the largest manner, 50×60 cm

- Bag height up to 20 cm

- Strong sealing without error

Vacuum pump of the machine

- Equipped with a rotary oil vacuum pump with very high suction power – 100 cubic meters from the Iranian brand Push.

- Available with vacuum pumps of 63 cubic meters, 100 cubic meters, 120 cubic meters, and 160 cubic meters.

- The high vacuum percentage enables the plastic pouch to adhere to the product, enhancing its beauty and shelf life.

Electrical Panel of the machine

- Separate and easily accessible electrical panel

- Suitable location for easy maintenance and repairs, ensuring protection against moisture penetration and possible damage

- Equipped with high-quality components from well-known brands

- PLC of the machine from Siemens

- HMI from Delta brand

- Temperature card from Delta

- PLC relays from PHOENIX brand

- Pressure terminals from Rade (Resistant to vibration and loosening)

- Contactor and thermal keys from Moller and/or Siemens

- Power supply and phase control from Omron qualified brand

- SSR relays of excellent and qualified type from Autonics brand

- Other parts from reputable brands available in the market

Frame of the machine

- Qualified 304L stainless steel body - Durable and shiny steel with high beauty.

- Use of qualified stainless steel resistant to corrosion and color change in contact with food and detergents.

- Unique and attractive beauty.

- Less dirt remains on this type of steel (shiny scratch-resistant steel), making it easier to wash.

- Strong and completely steel structure to prevent the device's accuracy from decreasing over time.

- Robust, durable, and sturdy structural design.

- Designed according to international standards and technical engineering principles.

- Long-term stability.

- Equipped with wheels for easier transportation.

- Utilization of high-quality 304 stainless steel, maintaining its appearance over the long term.

- The machine body is constructed from thick stainless steel sheets to ensure both strength and prevent a decrease in accuracy over time.

Keys and buttons of the machine

- Utilization of high-quality keys and buttons in the construction of the machine.

- Equipped with switches and keys from the Muller Germany brand, along with a special silicone coating from the mentioned brand.

- High safety during operator use, along with excellent washability.

- Emergency key with high-quality Muller Germany brand, ensuring a long lifespan and high safety during operation.

- The main machine key is from the Siemens brand with a high safety factor.

Usage of Angle Valves for quick and accurate setting of the vacuum path

- Angle Valves are controlled pneumatically, allowing them to benefit from high power and speed for opening and closing pathways. There are a total of 4 valves responsible for opening and closing the vacuum outputs.

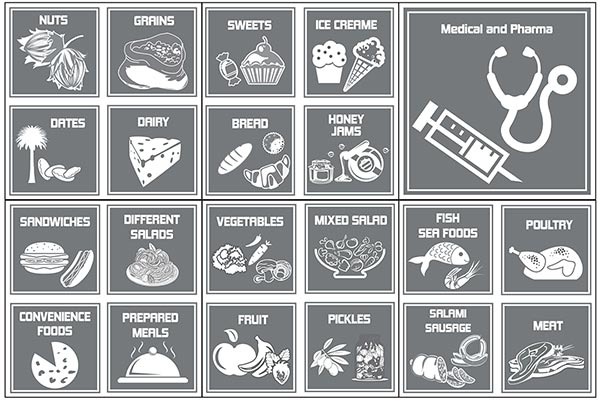

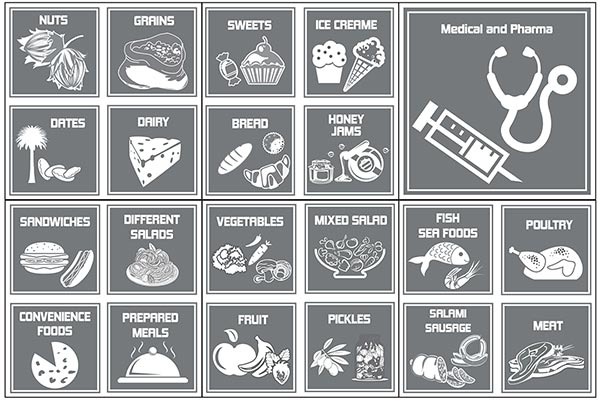

Applications of the machine in packaging

- Various nuts, dried fruits, and dates. MAP method prevents the growth of insects and larvae in dried products, increases crispness and shelf life and prevents their rancidity.

- Meals (such as Olivier salad, stew). MAP method causes preserving the minerals and vitamins in ready-to-eat and semi-prepared foods and prevents unpleasant taste in food products.

- Pickles (such as pickled cucumber, olives). MAP method is used to preserve the freshness of the ingredients in pickles and balance of the serum in these products.

- Red meat and meat from livestock. MAP method preserves the red pigments of meat, freshness, and also prevents oxidation of hemoglobin and myoglobin in these products.

- Poultry. MAP method preserves the color and texture of poultry meat and prevents spoilage reactions and undesirable odors in these products.

- Processed meals (sausages, salami; nuggets, hamburgers). MAP method preserves the freshness of the product and prevents quality loss and potential spoilage in packaging.

- Various seafood products (such as shrimp, fish). MAP method preserves the freshness, odor, and taste of seafood products and prevents oxidation and spoilage in these products.

- Vegetables, greens, and salads. MAP method preserves the pigments of grains in vegetables, greens, and salads and prevents their wilting.

- Various fresh fruits. MAP method is used to balance and preserve the respiration rate, freshness of fruits and preserves their organoleptic properties for a longer time.

- Dairy products. MAP method helps to preserve the main properties of dairy products (calcium) and prevents changes in color and taste, delaying spoilage.

Advantages of using the Vacuum Chamber Machine

- Precise packaging with a tight seal and standardized design.

- High precision and intelligence.

- High efficiency.

- High power and energy-saving.

- Hygienic design.

- Very strong and durable stitching.

- Internal cutting and beautiful, seamless stitching.

- Easy and quick cleaning

- Strong body structure

- Easy functionality and user-friendly interface

- Easy repairs and low maintenance costs

- Multi-purpose and multi-user capability

- Standard design

- Product shelf life increases by 3 to 10 times

- Increasing the beauty of package significantly

- Great assistance in branding

- Enhanced product sanitary

- Reduction in return of good extremely

- Increased in product exports significantly

- Significant sales increase due to valuable selling advantages

- Ultimately leads to increased profitability of the product