Cheese is one of the most delicious dairy products which contains many nutrients such as protein, vitamins, phosphorus, minerals, fiber, iron, etc. Consuming cheese has numerous benefits for bone health, heart health, dental health, and prevention of diseases such as cancer, diabetes, and osteoporosis. Therefore, using cheese without chemical preservatives is very beneficial, and proper packaging methods to prevent cheese spoilage during transportation, distribution, sale, and storage are of great importance. Packaging cheese using modified atmosphere packaging increases its shelf life without the use of chemical preservatives.

Steel West Asia Company is one of the manufacturers of cheese packaging machines. In this article, we will discuss cheese packaging methods and the use of packaging machines.

The Importance of Cheese Packaging

One of the most important aspects of marketing a product is its packaging, and cheese is no exception to this rule. Cheese packaging should be able to preserve all the taste, texture, aroma, and structure of the product. Similarly, it should be able to increase its shelf life as much as possible while protecting it from contaminants. If the product is to maintain its freshness "like the first day" over time, all of these functions are essential.

Requirements for Cheese Packaging

When packaging cheese, different factors must be considered. These factors include:

Protection against Light

Metals are non-permeable to light. Considering the packaging of fresh cheese, this primarily relates to aluminum, whether in the form of lids for plastic trays or in large trays. A high degree of light impermeability can be achieved by adding black or brown carbon pigments (light transmission equal to 0%). Since packaging cheese with a black color is not acceptable to consumers, such light-blocking layers are usually produced as inner sheets of multi-layer films with simultaneous extrusion. This packaging method is not used in dairy industries due to its cost. However, the barrier properties of aluminum in metallized plastic films (such as polyethylene terephthalate polyester PETP), oriented polypropylene (OPP), sulfone, or paper exist. To protect cheese from light, the product can be packaged in colored plastic trays or tin. Packaging in tin trays has a high cost, but plastic trays, besides protecting the product from light, are more cost-effective. These trays can be sealed using automatic packaging machines, by considering the fact that dairy products are very sensitive toward contamination, can minimize human touch. There are no limitations in choosing the color, shape, and dimensions of the tray.

Protection against Oxygen Effects

To prevent oxygen permeation, especially in fresh cheese packaged for long-term preservation, the least permeable packaging materials must be selected. This is achieved by using aluminum (foils or tapes), metallized plastics, or by using oxygen-resistant layers in plastic materials such as polyvinylidene chloride (PVDC), ethylene vinyl alcohol (EVAL), or polyvinyl alcohol (PVAL).

When selecting single-layer or multi-layer materials, it should be noted that gas permeability data always refers to smooth materials, measured at 23 degrees Centigrade. When a package is formed, permeability may change significantly due to wrinkles in sealed seams, thin sections in tray bases, or fractures caused by bending in bags.

The use of impermeable plastic trays and multi-layer gas-impermeable films (plastic, metallized, and aluminum) sealed firmly by seal vacuum machines, fully protect the product against gas permeation.

Protection against Moisture Loss

Moisture absorption does not have any effect on freshly packaged cheese. On the other hand, fresh cheese with a long shelf life must be protected against moisture loss. In addition to the specific vapor permeability properties of various packaging materials, the processing method of these materials into final packages is also important.

Packaging cheese using a seal vacuum machine prevents moisture from inside of the package and penetrating moisture from inside, as this type of packaging is completely impermeable. Therefore, the moisture amount of the cheese is fully preserved during the storage period.

Protection against Contamination

Apart from contamination through leakage in packages or lids, packaging materials themselves may be contaminated to a lesser or greater extent. Paper used as wrapping may be contaminated as raw material or during production by bacteria or molds.

Due to the high temperatures involved in processing, plastics are considered almost free of bacteria. However, during further conversion into films and trays, the possibility of contamination from the environment cannot be completely ruled out.

The automatic seal vacuum machine by Steel West Asia Company can constitute a complete packaging line equipped with automatic denester, UV tunnel, fillers, rowers, and traffic table, which, if used, can reduce human touch and minimize the risk of secondary product contamination. The UV tunnel sterilizes empty trays and reduces microbial load, while this type of packaging is completely firm and without leakage, minimizing the possibility of product contamination after packaging.

Considerations for Selecting Cheese Packaging Materials

When it comes to selecting the best packaging materials for cheese, several factors play a role. Understanding the characteristics of different types of cheese, preservation techniques, shelf life, and stability concerns are essential for making an excellent choice for your product.

Here are some considerations to keep in mind when choosing cheese packaging.

Type of Cheese and Characteristics

The type of cheese and its unique characteristics play a vital role in determining the most suitable packaging materials. Nowadays, grocery store shelves include a wide variety of food products, and cheese is one of the diverse products found in these aisles. It's good to know that what is the type of each of these colorful and diverse cheeses.

Let's examine the four main categories of cheese and their unique properties:

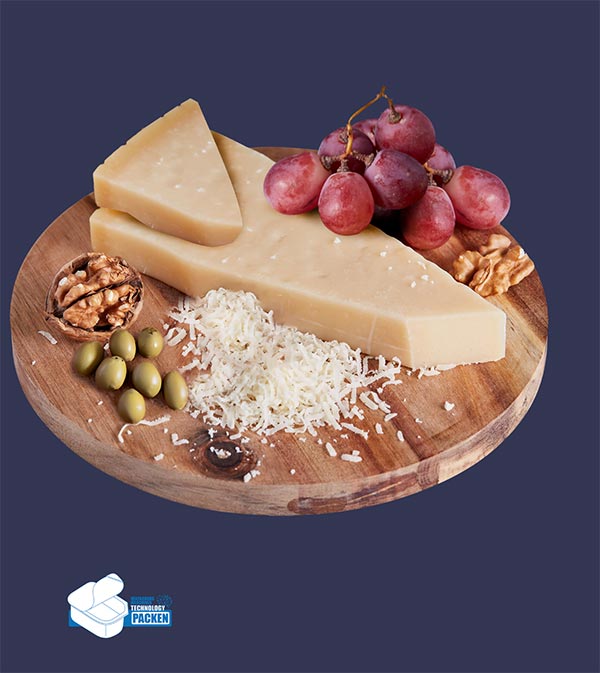

- Hard Cheeses: Cheeses like Parmesan and Cheddar have low moisture content and a firm texture. Packaging for these cheeses should protect them from further drying out while preventing exposure to external contaminants. Waxy coatings, vacuum-sealed bags, and vacuum packaging inside trays with plastic films and aluminum foil are popular options for hard cheeses.

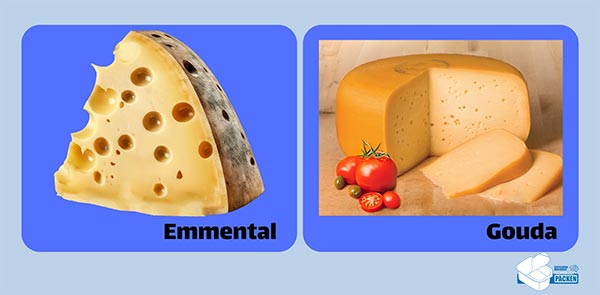

- Semi-Hard Cheeses: Gouda and Emmental are examples of semi-hard cheeses with slightly higher moisture amount than hard cheeses. They require packaging that preserves their shape and texture while preventing moisture loss. Vacuum packaging using modified atmosphere packaging (MAP) and waxed paper are commonly used for this category of cheese.

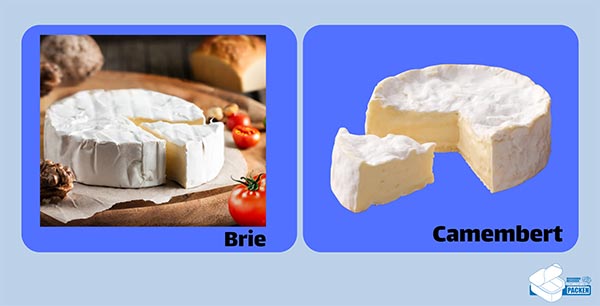

- Soft Cheeses: Brie and Camembert fall into the category of soft cheeses, characterized by a creamy texture and higher moisture content. These cheeses need packaging which maintains appropriate moisture levels while allowing some place for breathing. Greaseproof paper, breathable plastic wraps, and specialized cheese bags are ideal for soft cheeses.

- Fresh Cheeses: Fresh cheeses like Mozzarella and Ricotta have the highest moisture content and the shortest shelf life. Packaging for these cheeses should focus on preserving freshness, controlling moisture, and protecting against external contaminants. Plastic trays, vacuum-sealed pouches by vacuum, or modified atmosphere packaging can be used for fresh cheeses.

Cheese Preservation Techniques

Appropriate preservation techniques are essential for maintaining the quality and taste of your cheese. When selecting cheese packaging materials, consider the following points:

- Temperature Control: Cheese should be stored at an appropriate temperature to prevent spoilage and maintain its quality. Insulated packaging materials or those resistant to cold or freezing are very important for cheeses sensitive to temperature.

- Moisture Control: Packaging materials which help regulate moisture are essential to prevent excessive drying out or moisture in cheese. Wax coatings, plastic coverings, and packaging using modified atmosphere techniques are options that can control moisture levels during packaging.

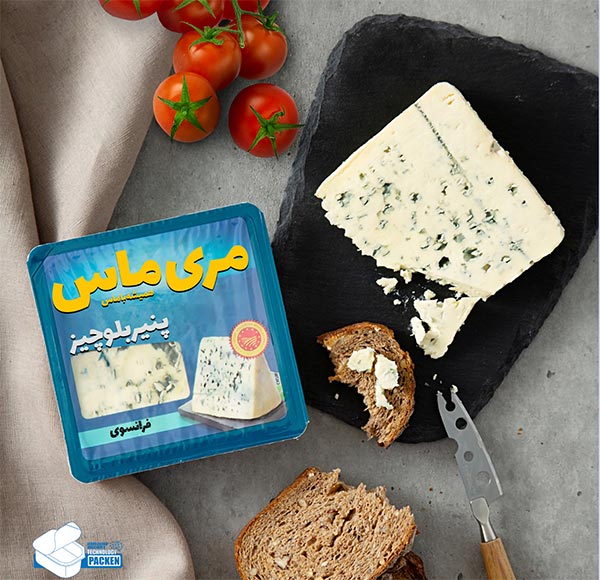

- Airflow Management: Different types of cheese require varying levels of airflow. While some cheeses benefit from limited airflow (such as soft cheeses), others may require more breathable packaging materials (like blue cheeses or Roquefort).

The Useful Life of Cheese and Its Expiration Date

When choosing packaging materials, it's essential to consider the shelf life of your cheese. Packaging solutions which help to extend shelf life, such as vacuum sealing, modified atmosphere packaging, or active packaging with antimicrobial agents (usage of UV for consumable trays), can be useful in reducing waste and ensuring the freshness of your product for consumers.

Sustainability and Environmental Compatibility

As consumer awareness of environmental issues is growing, it's essential to consider the sustainability of your cheese packaging material. Choose environmentally-friendly options such as biodegradable films, recyclable materials, or reusable trays to minimize your environmental impact and be attractive to environment friendly consumers.

Cheese Packaging Materials

Most persons who their favorite foodstuff is cheese and dairy producers benefit from a rich history and experienced techniques passed down through generations. In this section, we explore some of the most popular traditional cheese packaging materials that have stood the test of time. These classic methods are widely used today as reliable and effective tools for preserving the quality, flavor, and freshness of cheese.

Wax Coating

Wax coating has been a popular cheese packaging method for centuries. By placing cheese in a layer of wax, producers create a protective barrier that prevents the entry of air, moisture, and contaminants. This method is particularly effective for hard and semi-hard cheeses, as it prevents them from drying out while preserving their taste. Additionally, wax-coated cheeses have a unique appearance and visually appealing, making them different on store shelves.

Aluminum Foil

Aluminum foil is another widely used material for cheese packaging, providing a versatile and cost-effective coatings. The foil creates an excellent barrier against moisture and oxygen, aiding in the increasing shelf life of various types of cheese.

Moreover, working with aluminum foil is easy, and it can be firmly wrapped around the cheese. This coating prevents the cheese from unintentional exposure to air. Aluminum foil pouches are sealed using a vacuum chamber packaging machine, which creates a high percentage of vacuum that causes the aluminum pouch to adhere to the cheese and or alternatively, a certain percentage of vacuum can be injected with gas to preserve the quality and increase the shelf life of the cheese.

Paper

Paper-based packaging materials have been used in the cheese industry for a long time, providing a breathable and flexible covering for cheese preservation.

Greaseproof Paper Top of Form

Grease-proof paper is a paper that is a non-stick, impermeable to oil or grease paper which allows the cheese to breathe and at the same time protects it from external factors. This packaging is ideal for soft and semi-soft cheeses; because it helps to keep them moist without trapping moisture too much. Oil paper is also used to wrap cheese slices due to its ease of use.

Wax Paper

Wax paper is another popular option for cheese packaging, which has a thin layer of wax on both sides of the paper. The wax layer creates a moisture barrier that prevents the cheese from drying out and at the same time allows it to breathe. Wax paper is suitable for all types of cheese, including hard, semi-hard and some soft cheeses.

Plastic

Cheese is often packaged using food-safe plastics such as polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC). These materials create a barrier against oxygen and moisture and help maintain freshness and prevent spoilage. Vacuum-packed bags, plastic pouches, or plastic trays are usually used to package all kinds of cheese.

Plastic trays can be packed by various types of plastic, metallized and aluminum films by seal vacuum machines.

Glass Trays

Glass trays have been used to store and package cheese for years and offer an environmentally friendly and reusable method. These trays help to maintain freshness and prevent contamination. Glass trays provide attractive appearance which makes them a popular choice for specialized cheese supermarkets and high-level retailers.

Cheese Packaging Methods

In today's ever-evolving world, cheese packaging technologies have played significant role to ensure maintenance of quality and freshness. These innovative solutions are designed to meet the requirements of consumers and cheese producers.

Let's take a look at the latest developments in cheese packaging materials, including modified atmosphere packaging (MAP), edible coatings, active packaging and smart packaging technologies.

Modified Atmosphere Packaging

Modified atmosphere packaging is a pioneering technique which increases the shelf life of cheese by changing the composition of gases inside the packaging. By accurate setting the levels of Oxygen, Carbon dioxide and Nitrogen, the modified atmosphere creates an environment that inhibits bacterial growth and slows the spoilage process. This issue produces a cheese with a longer shelf life that maintains its taste, odor and texture.

Carbon dioxide has antibacterial properties, therefore it prevents the growth of spoilage microorganisms and Nitrogen will maintain the organoleptic properties of the product.

The purpose of modified atmosphere packaging is to eliminate or reduce the physical, enzymatic, and microbial degradation that spoils cheese. The rate of chemical reactions and the growth of microorganisms in modified atmosphere packaging will reduce.

Modified atmosphere packaging is also used for other products, including meat, fish, fruits and vegetables, dry products, etc. This process also makes it possible to reduce the amount of used additives and chemical preservatives.

Seal Vacuum

Seal Vacuum (vacuum packaging) is a modern method in packaging traditional cheese, which provides a protective barrier against air, preserving the freshness of the cheese and increasing its shelf life. By removing air from the packaging, vacuum prevents the growth of bacteria and molds, ensuring that the cheese stays fresh and flavorful for a longer time. This method is especially popular for preserving hard and semi-hard cheeses as well as pre-sliced cheese products.

Edible Coverings and Films

In efforts to reduce packaging waste and promote sustainability, edible coverings and films have emerged as environmentally friendly alternatives for traditional cheese packaging. These innovative materials are made from natural and biodegradable substances, ensuring their safety for consumption.

- Natural Materials: Edible coatings made from natural substances such as proteins, polysaccharides, and lipids can effectively preserve the quality of cheese while providing significant protection against spoilage. Examples of these coatings include whey protein, chitosan, and beeswax.

- Biodegradable Materials: Biodegradable films made from plant-based polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) offer a sustainable solution for cheese packaging. These films not only preserve the cheese but also naturally decompose, reducing their environmental impact.

Active Packaging

Active packaging technologies enhance the protective properties of cheese packaging by incorporating active agents that help prolong shelf life and preserve product quality.

- Antimicrobial Agents: By incorporating antimicrobial substances such as silver nanoparticles, essential oils, or natural extracts, active packaging can prevent the growth of harmful microorganisms and ensure longer shelf life for cheese products.

- Moisture Absorbers: Cheese packaging materials containing moisture-absorbing substances like silica gel or calcium chloride help regulate moisture levels and prevent agglomerating. These substances help maintain the desired moisture for cheese storage.

- Ethylene Absorbers: Ethylene absorbers such as potassium permanganate can be included in cheese packaging to absorb and neutralize ethylene gas. Ethylene gas is responsible for accelerating the ripening and spoilage process in certain types of cheese.

Smart Packaging

Smart packaging technologies provide a unique way to monitor and transfer important information about a product, ensuring desired quality and safety.

- Time-Temperature Indicators: These innovative labels change color or display a specific message based on the product's temperature-time history. These indicators help consumers determine whether the cheese has been exposed to unfavorable conditions or if it is still safe to consume.

- Gas Sensors: Gas sensors integrated into cheese packaging can detect the presence of spoilage gases such as ammonia and notify consumers to potential quality issues. This technology ensures that only the freshest cheese products make their way to your plate.

Modified Atmosphere Packaging (MAP) for Cheese

It may seem initially strange that cheese needs protection against microbes, as microbes play an important role in cheese production. However, while some microbes are beneficial for cheese-making, others can lead to spoilage. Totally, hard cheeses with low moisture content are susceptible to mold growth, while soft cheeses can be influenced by bacteria. Additionally, the fats in some cheeses are prone to oxidation by atmospheric oxygen, leading to cheese putrefaction.

Lactobacillus, widely used in dairy industries, can also pose problems as it lowers the pH of products, making them acidic. This issue can be exacerbated by improper packaging atmospheres with excessive levels of carbon dioxide.

Which Gas Increases the Shelf Life of Cheese?

Cheeses and dairy products are a large family of food products whose gas or gas mixture used primarily depends on the moisture amount.

Given the natural presence of microorganisms in dairy products, packaging in a modified atmosphere is effective for cheeses which are almost neutral.

Dry or Low-Moisture Cheese

These are products that are particularly sensitive to oxidation. Removing oxygen and replacing it with nitrogen (an inert gas) to prevent fat oxidation is essential.

Cheese with Medium Moisture Content For these products, there is a risk of microbiological development during storage, especially the growth of mold.

Cheese with Medium Moisture Amount

For these products, there is a risk of microbiological development during storage, especially the growth of mold.

The use of pure carbon dioxide or a mixture of carbon dioxide and nitrogen in packaging, depending on their moisture level and the existing microbial flora, will be suitable. Carbon dioxide effectively inhibits microbial activity and helps preserve the texture. If the concentration of carbon dioxide is less than 20%, it strongly inhibits the growth of molds.

The use of pure carbon dioxide or a mixture of carbon dioxide and nitrogen in packaging, considering their moisture levels and the existing microbial flora, will be suitable. Carbon dioxide effectively stops microbial activity and aids in preserving the texture. If the concentration of carbon dioxide is less than 20%, it strongly inhibits the growth of molds.

High Moisture Cheese

These products are particularly sensitive to oxidation and spoilage associated with yeast. Using a gas mixture of 30% carbon dioxide and 70% nitrogen to inhibit microbial growth and prevent souring through oxidation is appropriate. Hard cheese can be packaged in an atmosphere containing carbon dioxide, while for softer cheeses, this ratio is usually between 20 to 40 percent, with the remainder typically nitrogen. The main reason for this approach with softer cheeses is that over time, carbon dioxide can dissolve in the water inside the cheese, reducing the volume of gas in the packaging.

The main reason for this approach with softer cheeses is that over time, carbon dioxide can dissolve in the moisture present inside the cheese, leading to a reduction in gas volume in the packaging.

Ground or Sliced Cheese

Modified atmosphere packaging is especially beneficial for ground or sliced cheeses as it allows the space around the cheese to be preserved while it remains in the package. This space allows the cheese to breathe, enhancing its flavor, and also makes it easier for the cheese pieces to separate after the package is opened. Packaging in a modified atmosphere not only improves the shelf life of the product but can also have a positive impact on the taste and appearance of the cheese.

Value-added cheeses such as ground or sliced cheddar are also packaged in a modified atmosphere. Ground cheese is typically packaged in an atmosphere containing 70% nitrogen and 30% carbon dioxide. By limiting carbon dioxide to 30%, producers can prevent package collapse.

The shelf life of hard cheeses like cheddar, packaged in an atmosphere with high carbon dioxide, increases from two to three weeks in air to up to ten weeks in modified atmosphere packaging. Soft cheese, if kept in the air, usually lasts for eight days, but if placed in a suitable mixture of carbon dioxide and nitrogen, it can last for up to three weeks.

Different Types of Cheese Packaging Machines

West Asia Steel Company is one of the manufacturers of cheese packaging machines. The machines manufactured by this company include the following:

Automatic Tray Sealer Packaging Machine

One of the packaging machines commonly used for cheese is the automatic tray sealer. This machine packages products with high speed, accuracy, and quality. During packaging, the trays are placed automatically on the conveyor belt or by the operator. The empty trays pass through a UV tunnel for sterilization. Then, the filling machine fills the cheese into the trays (the filling machine is used for certain types of cheese). After the trays are filled manually or by the filling machine, depending on the type of cheese, vacuum sealing or packaging using modified atmosphere is performed. Once the packaging process is complete, the trays are moved towards the jet printer via a conveyor belt and finally collected on the traffic table.

Semi-Automatic Tray Sealer Packaging Machine

Another machine used for cheese packaging is the semi-automatic tray sealer. The packaging method of this machine is similar to the previous one, with the only difference being that some stages are performed by the operator.

Thermoforming Packaging Machine

The thermoforming packaging machine is also used for cheese packaging. During packaging with this machine, trays are formed using rigid or flexible films. After cutting the trays and forming them into various sizes and shapes, the filling process is carried out manually or by automatic filling machines. The filled trays are then packaged using vacuum or modified atmosphere packaging, and in the next stage, they are directed towards jet printer.

Manual Machine

The manual sealing machine is used for packaging foodstuff, including cheese, in small volumes and at low speeds. All packaging stages using this machine are done manually by an operator. The process of this machine involves placing the products into trays by the operator, and after placing the trays in the machine, the sealing operation is performed by pulling down the machine's lever. This machine is used for packaging products at home, in supermarket, or in small workshops.

Price of Cheese Packaging

Machine Steel West Asia Company is one of the reputable companies in the field of manufacturing packaging machines for various products. The machines manufactured by this company are available in different sizes and prices. The prices of the machines are influenced by different factors. Factors affecting the price of the machines include:

- The packaging method used in the machine

- The size of the machine

- The quality of materials used in the manufacturing of the machine

- Auxiliary equipment installed on the machine

- The shape and dimensions of the trays

- Whether the machine is automatic or manual

References

modifiedatmospherepackaging.com

Comments

Post comment

Comments sent by you will be published after the approval of the website administrator.