Olive is one of the nutritious foods that contains vitamins, minerals, organic compounds such as iron, fiber, copper, vitamin E, phenolic compounds, antioxidants, and etc. Therefore, attention to the preservation and maintaining of the quality of this food product is of great importance. One of the long-term preservation methods for olives while maintaining taste, odor, and quality is the use of modified atmosphere packaging.

One of the companies active in the production of olive packaging machines is the West Asia Steel Company. In this article, we will evaluate the methods of olive packaging and introducing the packaging machines for this valuable food product. Stay with us.

Olive properties

Olives are one of the main sources of unsaturated fats in the Mediterranean diet. The global production of olives reaches 1.5 million tons per year. Due to its high nutritional value, this food is considered as an inseperable part of the Mediterranean diet. In general, olive processing methods are employed to eliminate bitterness caused by phenolic compounds, hydroxytyrosol, and oleuropein. Olive processing is done using methods such as brining, other traditional methods like desalinating and cracking, as well as industrial processing like air processing.

Microorganisms play an important role in the production of natural compounds, especially in the field of food aromas. The primary goal of olive processing is to achieve the preservation and maintaining of the organoleptic properties (texture, taste, odor, color, and overall desirability) of the final product.

Olive processing involves various stages, and after washing and disinfection, the final product is stored at a low temperature or packaged using vacuum packaging or Modified Atmosphere Packaging (MAP). These techniques control the growth of fungi and, consequently, minimize the potential for mycotoxin production (fungal toxins).Storage at low temperatures (

Methods for Increasing the Shelf Life of Olives

One of the methods to increase the shelf life of olives is the use of edible coatings. These coatings have long been used to preserve and extend the shelf life of fresh fruits and vegetables. In this method, a semi-permeable membrane (by selective permeability) is formed on the surface, suppressing respiration, controlling moisture loss, and providing other functionalities. The usage of coatings on fresh agricultural products is typically done through immersion or spraying. Materials used in edible films and coatings include proteins, polysaccharides, and lipids, which may involve natural waxes and resins. Additionally, emulsifiers (substances used to stabilize emulsions) and softeners are added to improve coating performance. Edible films and coatings can serve as carriers for food additives such as colors, flavor enhancers, antioxidants, or antimicrobial compounds. The success of an edible coating in meeting the specific requirements of fresh and minimally processed fruits and vegetables depends on its inhibitory properties toward moisture, oxygen, and carbon dioxide.

Another method for increasing the shelf life of olives is Modified Atmosphere Packaging (MAP). This method is one of the most important preservation techniques that maintains natural quality and increases the shelf life of fruits and vegetables. Modifying the concentration of carbon dioxide and oxygen in the packages can reduce respiration and eliminate ethylene produced by olives during storage, helping to preserve the freshness and appearance of fresh products.

A study on olive packaging was conducted in normal air, nitrogen gas, and carbon dioxide. The results indicated that normal air was a good preservative for the coated olives. Additionally, olive packaging in a modified atmosphere containing 80% carbon dioxide and 20% normal air helped to preserve the qualitative characteristics of olives except for their color. On the other hand, packaging in a modified atmosphere with 100% nitrogen preserved the color of olives but did not preserve their firmness.

Packaging olives using the modified atmosphere method can stop the activities of microorganisms in the product and contribute preserving the product's quality. In this method, the growth of mold and other microorganisms in the product are controlled, resulting in increased shelf life, and the color and texture of the product are also preserved.

For the preservation of olives, low temperature and acidity are very important. The optimal temperature for olive preservation is 5 degrees Celsius, and the acidity of the product should be less than 3.5 and preferably above 0. Observing these factors has a direct impact on increasing the shelf life of the product.

Methods for olive packaging

The conditions for preserving olives play a significant role in increasing their shelf life, maintaining color, and ensuring the strength of the product. Therefore, selection the suitable method for packaging this product is of great importance.

Packaging olives is a way to enhance their economic value and expand the market. Olives are either supplied in bulk to domestic markets or exported to foreign countries. Generally, this popular product is packaged in glass or plastic trays, cans, and polyethylene, aluminum or multi-layered bags. These materials are filled with brine containing pH regulators, preservatives, antioxidants, softening agents, and sometimes gases such as carbon dioxide or nitrogen. Subsequently, pasteurization or sterilization is used to stabilize the product microbiologically.

In vacuum packagings, the product is placed in a package with low oxygen permeability, air is evacuated, and the packaging is sealed. However, the package atmosphere can be changed due to microbial metabolism and chemical reactions within the packaged food. Oxygen from the external environment can penetrate the packaging (unless packaging is done by machines like those of the Steel West Asia Company and an impermeable film and tray are used, the entry and exit of gases after packaging will not be possible). Therefore, over time, the atmosphere inside the package may differ from the original atmosphere.

Modified atmosphere packaging is one of the most important methods for preserving food products. This method includes creating a space consisting of carbon dioxide, oxygen, or nitrogen in the package, regulating the product ripening process, extending the shelf life, and controlling or reducing microbial spoilage during storage and distribution.

Fresh fruits and vegetables, continue to respire after harvest. During packaging by modified atmosphere packaging method, the amount of oxygen in the package decreases to slow down the respiration. Excessive reduction of oxygen in the packaging prevents aerobic metabolism, replacing it with anaerobic fermentation, which can lead to unpleasant odors and flavors in the food.

Research indicates that immersing olives in antimicrobial solutions before packaging and storing them under pressure in a carbon dioxide atmosphere at a temperature of 4 degrees centigrade effectively controls microbial activity, minimizes the production of mycotoxins, and preserves the quality properties of the packaged products.

Packaging olives using the modified atmosphere packaging (MAP) method can lead to the preservation of quality, increased product shelf life, more beautiful appearance, reduced production costs, elimination of chemical preservatives, and easy storage and transportation. However, the costs of packaging machinery, used gases, packaging materials, and analytical equipment for measuring gas mixtures are considered drawbacks of the modified atmosphere packaging method. Overall, the advantages of packaging using the modified atmosphere method outweigh its disadvantages. Overall, the advantages of packaging using the modified atmosphere method are more than its disadvantages.

Packaging olives in special trays or vacuum chamber pouches using vacuum sealing machines and vacuum chambers not only preserves the organoleptic properties of the product and extends its shelf life without the use of chemical preservatives but also facilitates easy and without leakage transportation. This method increases packaging speed, enhances the beauty and hygiene of the product, and differentiates your brand from other producers.

Advantages of olive packaging using the modified atmosphere packaging (MAP) method

Advantages of olive packaging using the modified atmosphere packaging (MAP) method include:

- Preserving freshness and extending the shelf life of the product

- Maintaining firmness, color, and the natural odor of olives

- Preventing spoilage and delaying the softening process of olives

- Preventing the growth of fungi and bacteria

- Increasing the sales of products and attracting more customers

- Easier transportation and reduction of product waste

- Reducing production and maintaining costs

- Preserving the quality of the product

Materials used in olive packaging

- Plastic trays: Including polyethylene (PE), polypropylene (PP), and...

- Metal trays: Metal cans, including aluminum and multilayered cans

- Glass trays

- Plastic pouches: Polyethylene bags

- Surface-coating films for packaged containers: Plastic films, metallized films, anti-fog films, aluminum films

Various types of olive packaging machines

Steel West Asia Company is one of the manufacturers of olive packaging machines. This company manufacturers various machines for olive packaging. The type of machines depends on the production capacity. The process of different types of olive packaging machines is explained below:

Automatic tray sealer packaging machine

One of the olive packaging machines is the Automatic Tray Sealer, manufactured by Steel West Asia Company. This machine is full automatically and efficiently packages products in plastic trays with high accuracy and speed. The procedure of working by this machine is described as follows:

- Initially, pre-made trays are placed on the machine either automatically or manually, and the product is loaded into them either automatically or manually.

- Subsequently, the trays containing the product are moving into the machine's mold, and packaging is done either ordinary or by utilizing the modified atmosphere packaging method, with the film being sealed onto the tray.

- After this stage, the packaged trays can be directed to the jet printer (date coder) or labeler, and after completing the abovementioned steps, they can gather on the turntable at the end.

Auxiliary equipment used for the production line of this machine includes:

- Automatic denesting system

- UV tunnel

- Converter of single row to multiple raw and vice versa

- Fillers

- Automatic rower

- Automatic lidder

- Traffic table

- Metal detector

- Weight control systems

Semi-Automatic Tray Sealer Packaging Machine

The operating method of the semi-automatic packaging machine with the rotary table from Steel West Asia Company is as follows:

- After the operator loads filled trays by the product on the machine's mold, rotates the table 180 degrees.

- The operator then signals the packaging order to the machine by pressing the keys.Top of Form

Manual sealing machine

A manual sealing machine is used for packaging different food products inside plastic trays. Due to its small size, this machine finds widespread usage in stores, workshops, and household packaging.

In this machine, placing the trays into the mold, removing the packaged products from the machine, and applying pressure to seal the film onto the tray's opening are done manually by the operator.

Thermoforming machine

Another manufactured machines from Steel West Asia Company designed for olive packaging is the Thermoforming Machine. The procedure of working by this machine is as follows:

- The thermoforming machine can package products inside plastic trays. The key difference between this machine and tray sealers (seal vacuum) is that the thermoforming machine manufactures the container itself. The film is placed on the machine and is then shaped by the forming mold. Packaging takes shape in the next step, and ultimately, the package is cut in the final mold.

- This machine can be equipped with various fillers. After the products are filled into the trays, they are guided to the sealing mold, and if necessary, vacuum and gas injection will take place. Following this stage, the film is sealed onto the tray, and in the next step, the cutting is performed, and the trays are moved out of the machine.

- After this stage, an automatic rower, jet printer, and traffic table are placed to complete the packaging line.

Vacuum Chamber Machine

Packaging of olives inside three-side sealed plastic, metallized, or aluminum pouches is also done. For packaging olives inside pouches,the vacuum chamber machine is used. This machine, designed in West Asia Steel Company, is structured to ensure that the olive serum or solution does not pour out of the pouch during packaging.

Operation of the vacuum chamber machine:

- The product is manually filled into the vacuum chamber pouches.

- The filled pouch is placed by the operator on one side of the machine cabin.

- The cabin is moved by the operator and put on the section where the pouches are placed. Pre-set settings such as vacuum level, gas injection, etc., are made on the touch control screen of the machine.

- While one side of the cabin is in the packaging process, the operator places pouches on the other side. This situation leads to an increase in speed and work efficiency.

The vacuum chamber machine is equipped with a 100 m3 vacuum pump and can create enough vacuum to ensure the pouch adheres completely to the product. The setting of this feature is possible.

Price of Olive Packaging Machine

The prices of different machines manufactured by West Asia Steel Company are influenced by various factors. These factors include:

- Capacity and speed of product production

- Types of produced products

- Used packaging method

- Size and dimensions of the machine

- Required auxiliary equipment

Therefore, before purchasing a product, carefully evaluate the required information and choose a suitable machine based on your company's production capacity and requirements. Contact our experts after considering all relevant aspects of the machine, and inquire about the price of the desired machine. They will provide you with a price estimate promptly and inform you about the payment conditions.

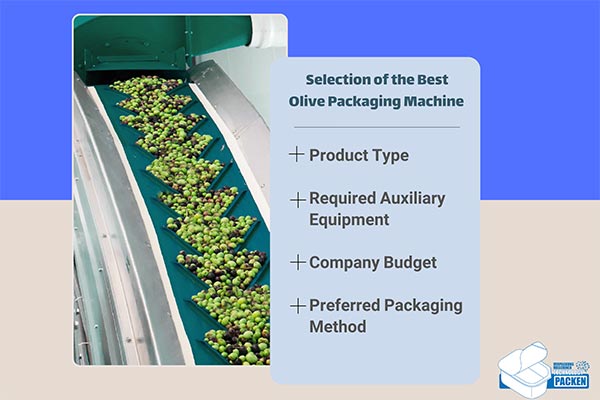

Selection of the Best Olive Packaging Machine

The most important step before purchasing a machine is determining the company's requirements, acquiring information about various machines, and becoming familiar with reputable manufacturing companies. Therefore, before buying a machine or setting up a production line, engage in reading about different machines, understanding their operational processes, consulting with experts, and more.

West Asia Steel Company is one of the most valid manufacturers of packaging machines. The company offers a variety of machines in different sizes, shapes, and price ranges.

One of the services of West Asia Steel Company is consultancy in the field of purchasing a qualified machine according to your requirements and budget. Therefore, before ordering for a machine, contact our consultants and experts to provide you with sufficient guidance. They will inquire about the following aspects:

- Product Type: The type of product determines the desired machine. For example, for packaging beverages, you need a filler machine to combine with a nitrogen gas cylinder.

- Required Auxiliary Equipment: The necessary auxiliary equipment is also among the most important factors when ordering a machine. In some cases, companies order equipment that does not significantly enhance packaging efficiency, or the absence of such equipment does not affect production speed. In these instances, our experts intervene and introduce you to the necessary and more practical auxiliary equipment.

- Company Budget: The budget of company for purchasing a machine is one of the most important factors when selecting a machine. In some cases, the budget set considered for a machine may be limited, making it challenging to purchase a qualified machine. In such cases, our experts recommend the best machine according to your budget. Additionally, you can obtain a more qualified machine by eliminating some auxiliary equipment and later adding additional auxiliary equipment during the packaging process.

- Preferred Packaging Method: The preferred packaging method is also an important consideration when selecting a packaging machine. In some cases, the modified atmosphere packaging (MAP) method significantly influences the appearance and quality of the product, leading to higher sales and attracting more customers. However, sometimes the MAP method may not be necessary for packaging your specific product. Therefore, our experts assess the packaging requirements of your product and recommend the most suitable packaging method accordingly.

Resources

Comments

Post comment

Comments sent by you will be published after the approval of the website administrator.