Semi-automatic vacuum sealing machine is used for packaging various food products in plastic trays.

Low required space and reasonable price for high packing capacities are the characteristics of this machine.

The operation of the machine

The procedure of working semi-automatic packaging machine by rotary table, designed and manufactured by West Asia Machinery Manufacturing Company, is as follows: Once the operator places the filled trays of the product on the machine's mold, the table must be rotated 180 degrees. Subsequently, by pressing the buttons, the machine will start.

The machine's mold is changeable and can be adjusted for trays by different dimensions. The process of mold changing is very easy and convenient due to its user-friendly design, and you can have several molds by one machine. Additionally, the parts used in the machine's mold ensure proper sealing during vacuuming, gas injection, and ultimately, packaging is done correctly and without error.

Comprehensive guidelines have been prepared to facilitate the settings of the machine, aiming to increase its efficiency. You can easily do the machine settings by following our experts' training, watching relevant videos, and referring to the guides provided by our company and achieving high productivity without any problems from this packaging method.

In designing and manufacturing of the semi-automatic tray sealer machine, this company includes a skilled technical and engineering department, a precise quality control department, and a highly equipped manufacturing department.

Introduction of different parts of the machine

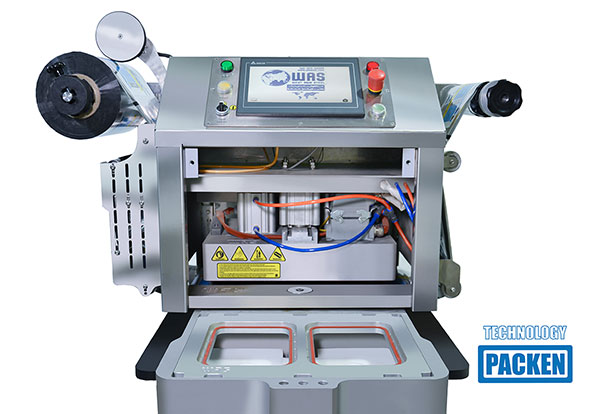

Touch control system (HMI)

- A 10-inch touch screen from the qualified Delta brand.

- Control settings for various parameters such as temperature, vacuum percentage, gas injection, ejection system, stepper motor, pressure, etc., are performed through the touch screen.

- With both English and Persian languages.

Waste Film Collector System (Stepper Motor)

Using a stepper motor with a high-precision drive:

- Achieving high accuracy in collecting film waste (as a stepper motor has much higher accuracy compared to an electromotor).

- By high IP (Ingress Protection) amount, making it resistant to dust and moisture.

- Possesses high Newton force and a long lifespan, preventing film sticking and tearing.

- Significantly reduces film waste.

- By capability to adjust the power and speed of film waste collection, offering valuable advantages such as:

- Capability to collect films made of aluminum, metallized materials, and polymer films by various thicknesses.

- Capability to adjust the pulling force during changes in film material and thickness.

- Ability to adjust the speed and prevent film tearing and wrinkling during product packaging.

Mold of the machine

By uniform casting and molding with very high accuracy, quality, and superior material.

By high resistant of mold against corrosion

Silicon bands placed on mold parts are well-designed and selected in various excellent qualities to ensure complete standardization and located in their respective positions.

Unique design of the machine's base plate.

Equipped with qualified 304 stainless steel pins and phosphor bronze bushes for smooth and accurate movement of the pins into the bushes.

Separate elements in seal molds.

Separate thermocouples for controlling the temperature of seal molds.

The blades have a separate system; the tooth profiles are precisely calculated and constructed and they are also placed on the mold in a way that the mold temperature does not have a direct impact on them and does not overheat them.

Two channels are connected to the mold shell to put all wires inside them and prevent them from interfering with the movement path of other parts inside the mold. This also makes repairs and maintenance easier.

Given the high technical knowledge and experience of Stainless West Asia specialists in mold design, it is possible to deliver molds with a higher number of cavities to customers.

Stainless West Asia has high capabilities in designing molds for packaging molds by different shapes and dimensions, and there are no restrictions in this regard.

The mold of machine can be change in the shortest time (up to 10 minutes).

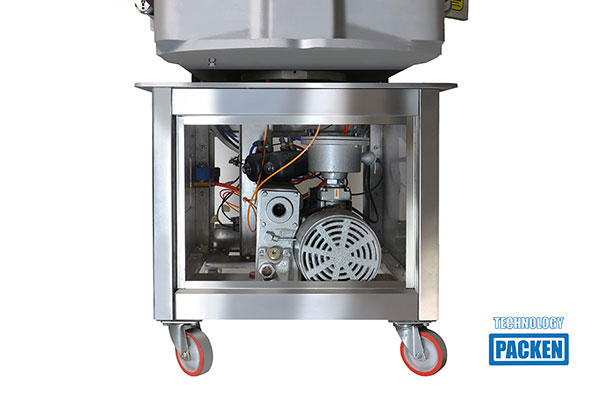

The frame of machine

The frame of the machine is made of qualified 304 stainless steel. The corrosion-resistant and shiny steel has doubled the beauty of the machine. The advantages of designing this part can be mentioned as follows:

- Qualified stainless steel that is resistant to corrosion and any potential color changes due to contact with food and various cleaning agents.

- It possesses stunning and unique beauty.

- In glossy, scratch-resistant stainless steel, very little dirt remains. It is also easier to clean.

- The strong and all-steel body of the machine prevents its accuracy decreasing over time.

- The usage of thick stainless steel sheets.

- Designed according to international standards and technical and engineering principles.

- Equipped with smooth wheels for easier machine transportation.

Table of the machine

- The table of the machine is designed to be rotatable and is made of qualified and uniform casting aluminum alloy.

- It has a highly effective sealing system for packaging products using Modified Atmosphere Packaging (MAP) method, ensuring high accuracy.

- It has a unique shape and beauty.

- The design observes engineering principles and necessary standards.

- It is easy to clean and hygienic.

- It is available with a protective coating to increase the lifespan of the machine and prevent discoloration due to contact with food and detergents (if requested).

- It prevents food accumulation in corners and prevents microbial growth.

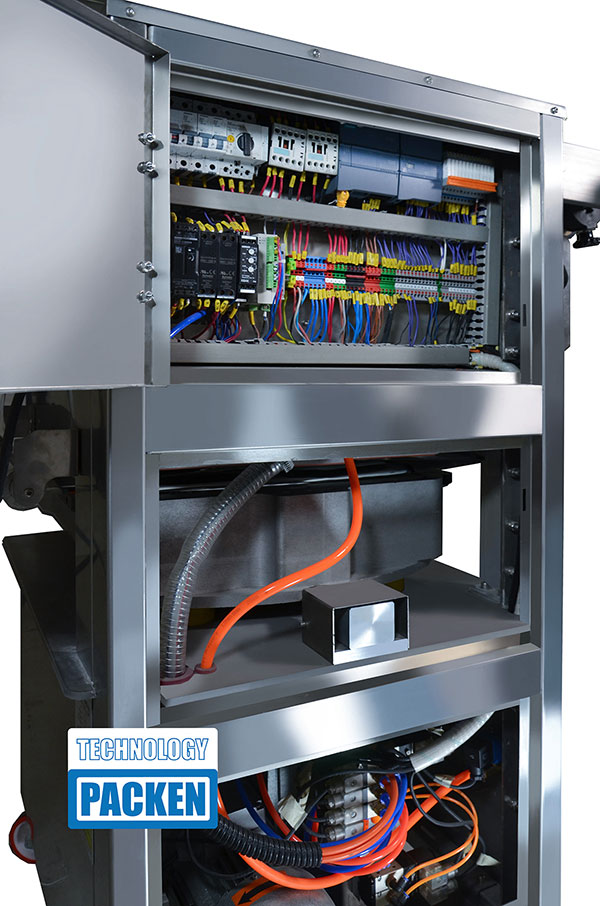

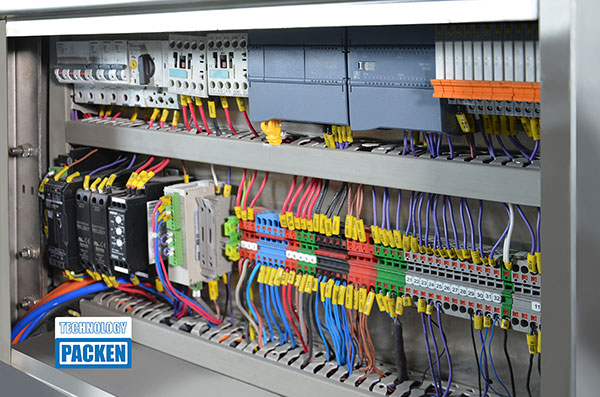

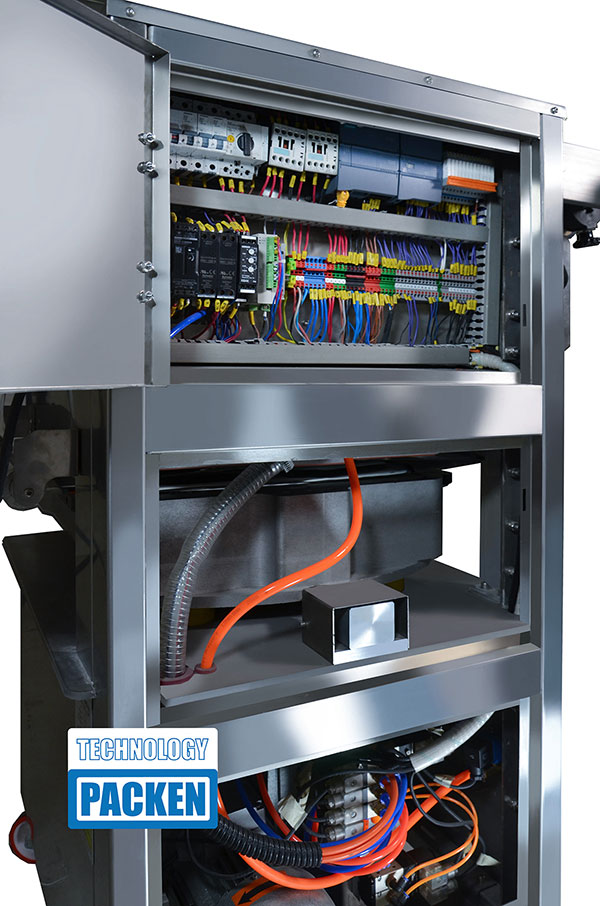

Electrical panel of the machine

West Asia Steel has made efforts to use the best and most qualified parts in the electrical department of tray sealer machine by rotary table. Number of the parts used are as follows:

- Qualifie PLC from Siemens brand

- HMI from Delta brand

- Temperature card from Delta brand

- PLC relays from Phoenix brand

- Raad push in terminals (resistant to vibration and loosening)

- Contactor and thermal keys from German brands such as Müller or Siemens

- Power supply and phase control from qualified Omron brand

- SSR relays from qualified Autonics brand

- SSR relays from qualified Autonics brand

- Other parts are sourced from top brands available in the market.

- The electrical panel is positioned at the back of the machine in a suitable place to ensure easy access to it.

Vacuum pump of the machine

The powerful vacuum pump of the machine has a capacity of 40 cubic meters and is from the qualified Iranian Puch brand. This results in an increased number of cycles per minute for the machine, allowing for more accurate and faster packaging of the product using the modified atmosphere packaging method.

Tray of the machine

The dimensions of the tray are 34*44 centimeters. Given the high knowledge of this company in mold design, you can use molds with more cavities to increase packaging speed.

PID system

The features of the PID system for controlling the temperature of the machine include:

- Very qualified PID from Delta brand.

- Accurate temperature control, ultimately leading to uniform and correct sealing (without deformation or having weak seal).

- The presence of up to 4 separate thermocouples for each mold, for increasing accuracy during packaging and individually controlling the temperature of the molds apart from each other.

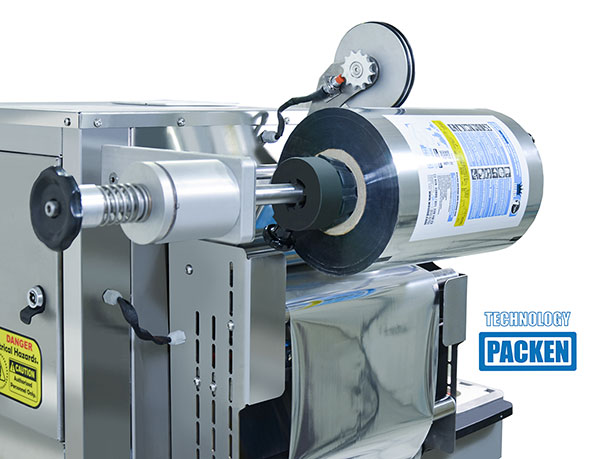

Guide Roller for Film

One of the important features of the machine is the use of multiple guiding rollers for the film:

To ensure correct film guidance, the machine utilizes 4 rollers. This helps in directing the film smoothly without wrinkles, preventing premature tearing during the packaging process.

All the rollers inside the machine are equipped with bearings to ensure smooth movement.

The rollers have adjustable bases and conical-shaped parts to significantly assist in guiding the film in its correct path.

Keys and push buttons of the machine

The machine is constructed using highly quality switches and keys with the following features:

- Switches and keys are from Müller Germany brand, accompanied by a special silicone coating (from the same brand).

- The operator benefits from high safety standards while using the machine.

- High capability of washing.

- It includes a qualified Emergency key from Müller brand, known for its durability and high safety.

- The main key is from the Siemens brand with a high safety coefficient.

The film roll brake system of the machine

A smart and accurate braking system has been used for controlling the unwinding of the film from the roll. This system includes:

Two film retaining rollers along with a professional bearing system designed to control the unwinding of the film from the roll and guide it accurately.

A professional braking system with easy setting, ensuring accurate control over the firmness or looseness of the film unwinding from the roll, according to the material type.

Viewing windows

The machine has four viewing windows, making repairing and maintaining easier.

Photocell

The sensor system for printed films on the machine is easily adjustable. This part is equipped with intelligent design features. On the left side of the machine, parts are placed to facilitate easy setting of the photocell to its correct position, resulting in a much lower error rate for detecting the accurate film position. Some features of this section include:

- Unique design

- Very easy setting

- Qualified sensor

- Presence of a high number of placed rollers

- Accuracy in the movement of the film in the correct path

The usage of angle valves (angle type valves) in facilitating the rapid and accurate setting of the vacuum path

The angle valves are pneumatically controlled and due to this pneumatic control, they possess high power and speed for quickly opening and closing the pathways. In total, there are four valves responsible for opening and closing the vacuum outputs.

The usage of accurate transmitter sensors for vacuum pressure control

The use of high-precision pressure transmitter sensors from qualified brands enables accurate control of the vacuum level inside the mold. The incorporation of these sensors is a crucial element that contributes to the accurate and correct performance of MAP (Modified Atmosphere Packaging) in the machines of this company. This sensor reads the pressure amount and sends it to the Programmable Logic Controller (PLC).

The advantages of the machine

- The technical standards used in this machine cause many benefits for manufacturer in packaging the product.

- The electronic parts used in the manufacturing of the machine are from reputable and qualified brands in the market.

- The use of qualified electro motors and gearboxes ensures the operation of machine without error and for a long-term.

- A powerful pneumatic system is employed for error-free packaging, performing the Modified Atmosphere Packaging (MAP) method accurately, ensuring firm sealing without error.

- Parts by high accuracy are used for the accurate placement of the table in its position.

- The use of parts by high accuracy ensures the placement of the film on the tray, creating a firm and aesthetically pleasing seal and cut.

- Qualified parts and accurate motion systems are employed to ensure the smooth and error-free operation of the machine.

- Stainless steel connections are used to prevent oxidation and potential damage.

- Stainless steel structure and body with corrosion-resistant material.

- Ergonomic and systematic design for easy cleaning of the machine and preventing damage to parts.

- Compact space requirement and affordable price.

- Design with high efficiency.

- Easy to use.

- Strong technical support.

- Mold changing time less than ten minutes.

- Minimal repairs and maintenance.

- Easy repairs due to the standard design of the machine.

- A simple and accurate system for precise and correct feeding of the film in its motion path.

- Accurate temperature control and adjustable sealing pressure.

- Smooth rollers with an appropriate number for the correct film transfer.

- By casting and molding rotary table and mold with high efficiency and unique beauty.

- User-friendly Human Machine Interface (HMI) and easy machine settings through the touchscreen (PLC).

- Automatic operation through robust automation.

- Approval by relevant food industry due to the hygienic structure and the fact that the machine is washable completely.

- Design of machine based on necessary safety principles during working by the machine.

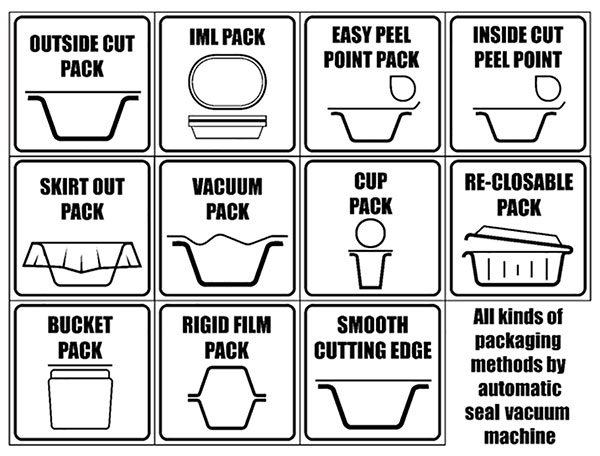

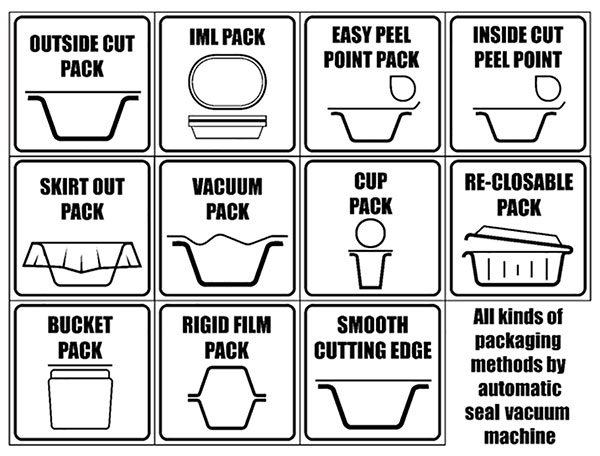

Types of packaging methods

- Outside Cut Pack. This method of packaging is the most common type of packaging. In this case, the film is cut from 2 to 2.5 mm from around the tray and then packed on the opening of the tray.

- Easy Peel Point Pack. This type of packaging is used for products that the film should be easily removed from the tray opening when using. Therefore, the tab created by this method can help to do this more easily.

- IML Pack. In the In-Mold Labeling (IML) method, packaging of food products in IML trays can result in the creation of a unique aesthetic appeal in the packaging. IML trays are labeled during the production process. These types of trays have edges with a narrow width, requiring them to be packaged with specific technology due to this characteristic.

- Vacuum Pack.In this method, "skirt all pack," after packaging, a film is placed in a skirt-like manner around the tray.

- Inside Cut Peel Point.This packaging method is a combination of Peel point and Inside Cut method. In this method, the film is cut with a distance inside the edge of the tray and then a tab is created next to it to make easier for the consumer to remove the film from the opening of the tray.

- Bucket Pack. Products that must be placed in buckets should be packed by this method. The buckets usually have high heights.

- Cup Pack.Packing of round opening containers is done by this

Application

Semi-automatic tray sealer packaging machine is designed for workshops and factories with low level production, the most important features of which are the small dimensions of the machine and its ease of usage.

Additionally, this machine is used in large manufacturing factories that aim to package products on a small scale for initial testing and also market research. Therefore, after necessary experiments, and trial-and-error processes, they determine how to manufacture their products on a larger scale.

Products packable by the machine

- Pickles (such as pickled cucumber, olives). MAP method is used to preserve the freshness of the products in pickles and balance of the serum in these products.

- Meals (such as Olivier salad, stew). MAP method causes preserving the minerals and vitamins in ready-to-eat and semi-prepared foods and prevents unpleasant taste in food products.

- Dairy products. MAP method helps to preserve the main properties of dairy products and prevents changes in color and taste, delaying spoilage.

- Various nuts, dried fruits, and dates. MAP method prevents the growth of insects and larvae in dried products, increases crispness and shelf life and prevents their rancidity.

- Bakery and confectionery products. MAP method prevents moisture loss in the products. This method helps preserving the odor and taste of the products for a longer period and also prevents mold formation in these products.

- Medical and pharmaceutical products. We are capable to provide completely hygienic packaging with suitable and sterile materials by the customer's desired method for medical and pharmaceutical products.

- Various fresh fruits. MAP method is used to balance and preserve the respiration rate, freshness of fruits and preserves their organoleptic properties for a longer time.

- Vegetables, greens, and salads. MAP method preserves the pigments of grains in vegetables, greens, and salads and prevents wilting.

- Various seafood products (such as shrimp, fish). MAP method preserves the freshness, odor, and taste of seafood products and prevents oxidation and spoilage in these products.

- Red meat and meat from livestock. MAP method preserves the red pigments of meat, freshness, and also prevents oxidation of hemoglobin and myoglobin in these products.

- Poultry. MAP method preserves the color and texture of poultry meat and prevents spoilage reactions and undesirable odors in these products.

- Processed meals (sausages, salami; nuggets, hamburgers). MAP method preserves the freshness of the product and prevents quality loss and potential spoilage in packaging.